Hybrid Research Has Educational Impact

A team of undergraduate and graduate engineering students at the Georgia Institute of Technology (Atlanta) has spent the past two years designing, building and testing a hydraulic hybrid propulsion system retrofit and biofuel conversion of a public school bus donated by the Atlanta Public Schools. To date, their work has helped realize the potential of new fuel efficiencies for school buses.

School buses were selected as the vehicle of choice for hydraulic hybrid power research because of their large mass and stop-and-go drive cycles. The hydraulic retrofit designed by the team at Georgia Tech captures braking energy using a pump-motor, which first pumps hydraulic fluid into a high-pressure accumulator (thereby storing energy), and then releases this energy to the drivetrain through the pump-motor. A microcontroller-based system, also developed at Georgia Tech, controls the pump-motor, its displacement and various valve components.

Next steps in the research project involve incorporating clean start technology, in which the diesel engine is shut down at bus stops and restarted using a hydraulic motor. The idea behind using the clean start technology is to help avoid having children breathe emissions when the bus is stopped and idling as children get on and off the bus.

Testing is now being conducted to determine if the bus can meet the predicted gains of more than 20 percent in fuel economy. In Atlanta alone, this level of fuel efficiency improvement could save about 140,000 gallons of diesel fuel a year.

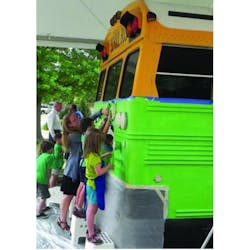

An added benefit of this research has been discovered in its effectiveness in engaging college and pre-college students in hands-on learning about eco-friendly fluid power. As more undergraduate and graduate students get involved with the project, some are taking on the role of teacher as they use the bus to show pre-college students how hydraulic systems operate and why the work of engineers is so important.

The project, originally funded by grant from the Ford Motor Company Fund, has received additional donations of components as well as guidance from engineers at Eaton Corporation, Evonik RohMax, Linde Corporation and Poclain Hydraulics, all of which are industry affiliate members of the Engineering Research Center for Compact and Efficient Fluid Power (CCEFP). The CCEFP will provide funding for work during the project’s third year.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: