Electric motors use almost half of the world’s energy. In an industrial environment, 40 to 70 percent of the electricity consumed by a plant is used to drive electric motors. So even 1 percent gain in motor efficiency can save tens of thousands of dollars in electricity. That fact has led governments across the globe to mandate the use of more efficient motors—and those mandates are spurring operators of manufacturing and continuous-process plants to invest in more efficient motor technology.

That was the crux of the message from Alex Chausovsky, manager and principal analyst for IHS technology group, who spoke at The Automation Conference. His keynote presentation explained the impact of motor efficiency legislation being enacted in various global regions, and the effects that more expensive higher-efficiency motors are likely to have on the repair vs. replace decisions facing motor users.

With new motor efficiency standards on the horizon, decisions related to repairing or replacing aging or damaged motors are likely to become both easier and harder. The U.S, European Union and other countries that are mandating the use of so-called “premium efficiency” motors, which come with both higher upfront costs and expanded energy savings potential.

“In the U.S., NEMA Premium is the standard now (rather than Epact standards) and is 10 or 20 percent more expensive. Yet, in the U.S., we’re still one efficiency band higher than what we see required in the rest of the global market,” explains Chausovsky.

What has been the effect of the legislation, and just how effective are the regulations in getting new technology used? “We’re seeing price increases of 5 to 6 percent per year [on motors] because of the legislation,” says Chausovsky. That is partially because, in the U.S. and China, regulations only focus on motors.

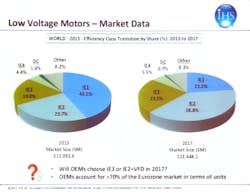

“In Europe, they include VFDs [variable frequency drives] in regulations, which means high-efficiency motors themselves are less important,” says Chausovsky.

Fan and pump applications need VFDs, for example. But not all applications do. "In the right application, VFDS can provide up to 70 percent energy reduction over just improving the motor alone,” Chausovsky says.

“If the more holistic European approach spreads, due to the efficiency successes achieved in Europe with this approach, it could have a big effect on the market,” Chausovsky adds. IHS predicts the machinery market for motors will grow 6.3 percent in 2014, while the process industries are expected to increase capital expenditures by 5.4 percent for motors. Chausovsky says that he sees a great potential for growth for the intelligent motor control market. He expects this market to grow even more than the general motor market.

Even given the higher costs of new, more-efficient motors, 95 percent of the money spent on a motor over its lifetime is for the energy used to run it; only 5 percent goes toward the initial purchase price and regular maintenance, Chausovsky says.

“Motor duty cycles are large. Some have been used for much longer than what they were designed for,” said Chausovsky. “We’ve seen motors that are 30 and 40 years old. They have been rewound, and they are still running.”

For more IHS information on how sales of premium-efficiency motors are being affected by government regulation through 2018, visit http://www.automationworld.com/motors/ie3-motor-revenues-boosted-regulations.

About the Author

Renee Bassett

Managing Editor

Leaders relevant to this article: