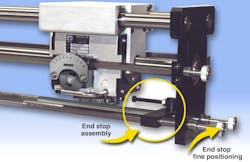

The option makes possible more precise location of the drive unit reversal points, which is useful in linear motion applications where precision setting of the reversal points enhances process accuracy and integrity. Suggested applications are in production equipment including converting/packaging machinery, wire/cable spooling equipment and other automated machinery with a linear motion component. In the company's standard linear drive assembly the end stops determining stroke length are situated on hex rods held in place with set screws. Users loosen the set screws, slide the stops to set the travel distance, then re-tighten the set screw. The fine adjustment option has the end stops positioned on threaded rods. The rods extend through the pillow block end supports and a control knob is mounted on the end of each rod. Turning the control knobs rotates the threaded rods causing the end stops to move in very fine increments. This permits accurate location of the reversal points resulting in a higher degree of precision in applications such as level winding, spray coating, scanning, slitting and other reciprocating linear motion processes. Drives are available in seventeen sizes with axial thrust from 7 to 800 pounds.

>>For more information on this product, click here

Amacoil, Inc.

www.amacoil.com

610-485-8300