Saving Energy with OPC Unified Architecture

It has probably happened to all of us at one time or another: You leave the house or office and after a while and several miles later, it suddenly occurs to you that you have left a window open and the heating is on. Now you have to decide whether it makes sense to head back or to put up with the additional heating costs. Another example: The installed solar thermal system was meant to reduce your energy costs, however, after looking at the bill from the power company you realize the exact opposite is happening. What happened, why is the system not working as expected? Well, some tiny little detail has caused the integrated control to fall back on standard energy sources such as fossil fuels or district heating. This is a real-world case that has been observed particularly with large solar thermal systems for multistory residential buildings.

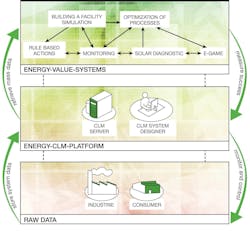

The Austrian company NTE Systems [1] has developed a system to visualize energy consumption using the web based building control system Scady (from “SCADA easy”). This lays the foundation for taking effective energy saving measures. The use of standards promotes the integration of various technical systems with influencing factors like, for example, the weather using the Internet as the data exchange media. Such a system can help to create simulations, forecasts, and derivations regarding future events in the building.

Building control system with OPC UA

The requirements for the building control system, as defined by the manufacturer, were focused around cost-effectiveness, high-performance, and an easy-to-use software solution. It has to be deployable in both industrial and end-user applications with minimal engineering effort.

It turned out that the OPC Unified Architecture communication standard was a perfect fit to meet the requirements. Using OPC UA, the system can process, change, and visualize the data from a PLC or other electronic controller over the Internet. The building control system is used for the continuous monitoring of existing systems and provides the foundation for system optimization, energy efficiency improvements, and, consequently, cutting costs.

When compared to proprietary technologies, OPC UA has the advantage that it only requires the implementation of a single communication protocol for exchanging the data between disparate control systems from different manufacturers. This reduces maintenance work – and thus maintenance costs – while increasing communication stability.

With its service-oriented architecture and the use of the W3C standards provided by the World Wide Web Consortium, OPC UA opens up new application possibilities, such as platform independence, Internet capability, and protection against unauthorized data access or data loss by implementing data security and redundancy concepts.

Scady leverages these advantages and allows an authorized user to monitor and edit the system data from anywhere in the world – provided that Internet access is available. The security measures meet the same stringent requirements as are applied to banks, and triple redundancy ensures high system availability.

High level of utilization

After extensively evaluating different approaches for implementing the OPC UA standard plus testing different OPC UA development tools, NTE Systems settled on Softing's OPC UA Client Toolkit. “This product has proven to be the most reliable OPC UA solution for us. In addition, the software is designed to run in a 64-bit Windows server environment,” explains Andreas Hafellner, Development Manager at NTE Systems. “Besides system openness, it was, above all, the enormous data throughput and the simple programming interface that convinced our product development team. What is more, with Softing's OPC UA Client Toolkit we reached our project goal several months earlier!”

A customized OPC UA Client Toolkit version specially developed for NTE Systems by Softing allows the management of more than 1,000 systems simultaneously in the Scady System Designer. The integrated access rights management functionality regulates who is allowed to access what data in the system.

Reference project in residential complex

Today, NTE Systems has installed the new system in a residential complex in Graz, Austria, to monitor and operate an entire local heating grid of several buildings, a heating system in 59 residential units, and a 300 m2 solar thermal system. PLCs from Beckhoff [2] with an integrated OPC UA server are controlling the different systems. Operation and monitoring is performed centrally through Scady.

Communication over the Internet is realized with an OPC UA client that NTE developed using the Softing OPC UA Client Toolkit. “After we connected the PLC to the Internet, all the data items were visible to the Scady System Designer as soon as we entered the IP address of the PLC. Next, we created the complete visualization using the drag-and-drop functionality of Scady. It couldn't be any simpler,” says Georg Stasny, Managing Director of NTE Systems. As Andreas Hafellner sums up: “OPC UA gave us the means to implement an end-user ready, ‘no programming required’ remote control and monitoring platform for PLC data over the Internet.

“This would have been technologically impossible or at least extremely difficult to implement using OPC and COM or similar predecessor technologies. What is more, in Softing, we have found a partner with extensive know-how and expertise when it comes to industrial communication.”

For more information: http://www.softing.us or Tel: (978) 499-9650, Fax: (978) 499-9654, Email: [email protected].

About the Author: Dipl.-Ing. Jürgen Lange is Market Segment Manager at Softing Industrial Automation. He also represents the company at OPC Europe and at the Technical Advisory Council of the OPC Foundation. E-Mail: [email protected]

Bibliography

[1] NTE Naturenergie. Technology and Engineering GmbH, Graz/Austria: www.ntesystems.at

[2] Beckhoff Automation GmbH, Verl/Germany: www.beckhoff.de