ARC View: FDT Finds Favor for Factory Fieldbus Flexibility

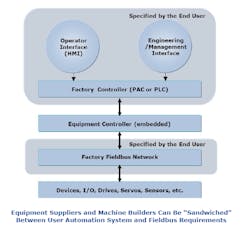

Factory equipment suppliers and machine builders, even major ones, must comply with the system specifications demanded by end user manufacturers. As a result, they must deliver their products to support one of many different combinations of factory automation system and fieldbus. ARC spoke with one major equipment supplier that now uses FDT to increase product flexibility without adding permutations to its product design.