Easy-to-Use Field Device Parameterization and Diagnostics

FOUNDATION fieldbus (FF) has become a leading fieldbus technology for petrochemical applications and other process industries that typically control complex processes with several thousand measurement points. Its advantages include increased data accuracy and enhanced system reliability through digital technology, as well as diagnostics that improve plant availability. Easy expandability, reduced costs over the product life cycle, improved reproducibility of individual processes, and reduced installation and cabling are additional benefits.

The sheer number of controllers and field devices as well as the installation and commissioning efforts often add up to a large investment amount, so these systems usually run for years. That means users will need to replace outdated components or to expand one part of the processing plant while the rest of the facility continues to work.

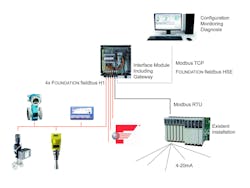

Softing’s FG-110 FF Linking Device and Gateway is designed to enable plant operators to do exactly that. Any legacy control system that supports the Modbus protocol can be integrated with modern field devices. On the fieldbus side, four FF H1 segments can connect up to 64 field devices.

At the same time, the FG-110 FF may act as a FOUNDATION fieldbus Linking Device that "links" H1 networks with applications utilizing the High Speed Ethernet (HSE) protocol. The Linking Device functionality allows the easy integration of modern applications for device configuration, monitoring, and diagnostics of FF H1 segments. The FG-110 FF is also used within the Softing FIM-110 FF interface module. A sample FG-110 FF architecture is shown in Figure 1.

Commissioning and maintaining a FOUNDATION fieldbus network is performed in several steps. In a step, the network and device configuration is defined using a configuration software tool. This includes the assignment of network addresses as well as Function Block linking and scheduling. Next, users must parameterize individual field devices and finally to access diagnostic information provided by the field devices. These tasks are performed by using a manufacturer specific tool or an Asset Management system.

FDT Technology provides an elegant solution for Asset Management Systems. FDT offers a fieldbus-independent, open, and standardized interface to access field device information for configuration, parameterization, and diagnostic purposes. FDT provides an interface tool, a Frame Application that performs the data exchange with the individual devices in the network for parameterization or fault diagnostics in a uniform way using the standardized FDT Technology.

FDT Frame Applications are available from different manufacturers such as SMART VISION, FieldMate, Field Device Manager, PACTware, ec. A combination of appropriate drivers are loaded into the FDT Application and linked as needed according to the specific network components. Each driver (Device Type Manager, DTM) is a software module that supports all device-specific data, functions and graphical controls. The FDT standard defines three different types of drivers: While the Device DTM represents the specific field device in the network, the CommDTMs (communication DTM) represents a communication device, which acts as a master on a fieldbus network. In addition, a GatewayDTM is the software representation of a physical gateway between two fieldbus segments of typically different protocols and/or physical properties. Figure 2 presents an overview of an FDT Frame Application.

In order to integrate Softing's Linking Device and Gateway with a standard FDT Frame Application two DTMs are required: The first DTM is the FF HSE CommDTM. It permits accessing a FOUNDATION fieldbus HSE network by the FDT Frame Application, acting just like any other FF HSE device in the FF HSE network.

The second DTM is the Linking Device Gateway DTM. This DTM supports the complete protocol-specific and device-specific management that is required to communicate with field devices on any of the supported four FF H1 segments and includes FF H1 host functionality.

The two FG-110 FF specific DTMs ensure a seamless integration of standard FDT Frame Applications like SMART VISION, FieldMate, Field Device Manager, PACTware, etc, with Softing's FG-110 FF or Softing’s FOUNDATION fieldbus Interface Module FIM-110 FF. For example, the connected FF H1 field devices are automatically detected and identified and the according device and manufacturer information is displayed in the generated live list.

Softing has released the version V1.30 of the FG-110 FF DTMs. These DTMs can be downloaded from the Softing website free-of-charge and can be used without a license key.

For more information on Softing’s Linking Device Gateway, and DTMs, click here.