iDTM-FDI. Simply Integrated.

The world premiere of “a seamless connection between FDI and FDT” was presented at the Field Communication Lounge at this year's Hanover Fair in the FDT Group booth showcased in a brewery application.

Visitors from the fields of process and factory automation saw, for the first time, the interaction of two key integration technologies, FDT and FDI software components working together within a new product called iDTM-FDI.

During the press conference, Dr. Rolf Birkhofer, Managing Director of Karlsruhe-based integration specialist CodeWrights, and Mr. Glenn Schulz, Managing Director of FDT Group, detailed the benefits of using iDTM to integrate FDI into FDT hosts.

Though much has been said about the link between FDI and FDT, many visitors were excited to discover that a running product combines the two technologies smoothly. This means also that end users no longer have to choose between the two technologies.

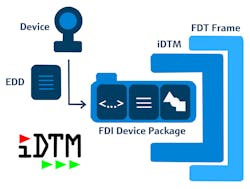

The iDTM-FDI continues the iDTM (interpreterDTM) principle, first introduced for HART and FOUNDATION fieldbus devices a few years ago. A brewery demo in the FDT Group booth showcased how FDI Device Packages can be used by any FDT2 Frame Application. Plant operators can fast and easily communicate with different field devices using FDI Device Packages inside the iDTM-FDI over the well-known FDT communication mechanisms.

The iDTM-FDI is useful for both end users and FDT system vendors. Because FDI Device Packages contain EDD files that are the controlling elements for the iDTM-FDI, device manufacturers can also utilize this software for their dedicated DTM development. The benefits are manifold:

#1: Reduced Development Time

iDTM-FDI helps to minimize driver development and testing. With now three technologies, EDD, FDT and FDI, device manufacturers are expected to provide an additional artifact, the FDI Device Package. By using iDTM-FDI, the FDI Device Package can be used for FDI host applications and FDT based host systems without changing the FDI artifacts in anyway.

#2: Low Life-Cycle Cost

FDI Device Packages, the tool set and the common software components offer backward compatibility with regard to the interpreter and the EDD files. The iDTM-FDI software also allows device manufacturers to update FDI Device Packages by themselves.

#3: Harmonized Functions and User Interfaces

Device manufacturers are expected to provide common functions and user interfaces for all major integration technologies (FDT, EDDL, FDI). iDTM-FDI lets them bring up the complete FDI Device Package function set and user interface without altering a single line of code.

This is what you can expect from the CodeWrights iDTM-FDI product:

• iDTM-FDI is the simple path into FDI: no dedicated FDI Host is required, look and feel stays the same, devices with no FDI Device Packages available can still be managed via DTMs or iDTM.

• FDI Device Packages can be used without changes.

• iDTM is a proven technology as iDTMs for HART and FF have been certified.

• iDTM-FDI is a perfect migration path for FDT2 system vendors in process and factory automation.