Although manufacturing is a core enabler of the Internet of Things, many industrial companies don't fully understand the capabilities of the cellular communications technology that can enable it. Wireless Ethernet or wireless serial radios certainly have their place in industrial facilities, but cellular M2M devices designed for industrial automation applications are another option, and are increasingly being installed.

According to a new research report from the analyst firm Berg Insight, shipments of cellular machine-to-machine (M2M) devices in industrial automation reached 760,000 units worldwide in 2013. Growing at a compound annual growth rate of 22.5 percent, shipments are expected to reach 2.1 million units in 2018.

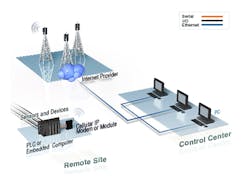

M2M supports wired or wireless communication between devices. Backbone network communication and remote monitoring are the two largest applications for cellular M2M connectivity within industrial automation, says Berg senior analyst Johan Svanberg, whose areas of expertise include embedded connectivity, wireless M2M markets and mobile applications. Remote service maintenance, including diagnostics of machinery and industrial robots, is a major application within factory automation. Real-time monitoring of remote facilities and equipment is one of the most common applications within continuous-process automation.

Cellular is only part of the industrial communications mix, and connectivity requirements vary depending on the application, but “the combination of wireless technologies such as Wi-Fi, cellular, WirelessHART, ISA100 and Bluetooth can provide ubiquitous online connectivity at reasonable cost, delivering very high performance as well as excellent availability,” says Svanberg.

Mike Granby, president of Red Lion Controls, says “a clear value proposition” exists for remote connectivity and it is driving the current boom in cellular M2M connection. “Consider Metcalfe's law as it applies to the Connected Factory: The value of the network increases exponentially with the number of connected assets. With this in mind, manufacturers must invest in issuing all remote assets a cellular connection,” he says.

Cellular routers and modems now provide native support for industrial automation equipment and protocols, including models that support 4G network connectivity. These products enable two-way communications from facility to facility, and enable information exchange with remote assets.

Of the more than almost 1 million devices shipped in 2013, cellular network equipment shipments reached 530,000 worldwide in 2013, says Svanberg. This product grouping, which including gateways, switches, connectors, routers and wireless access points, is the largest industrial automation M2M device segment.

Automation equipment featuring embedded cellular connectivity includes machinery, industrial robots, RTUs, PLCs, DCSs, sensors, I/O modules and operator terminals. These shipments reached 230,000 devices in 2013, says Svanberg.

Svanberg predicts LTE network technology will further increase cellular adoption in industrial automation, even in control applications. “A new generation of high-capacity LTE cellular networks will address the growth in demand for data hungry applications such as video monitoring, as well as spur innovation of new applications,” says Svanberg. LTE also will increase the use of cellular communication in industrial backbone networks, which comprise the largest application for cellular M2M within both factory and process automation, he says.

The LTE network’s shorter latency times will enable cellular connectivity to be used in an increasing number of remote control applications—which is already a key driver for cellular M2M applications, adds Svanberg.

The market is served by a multitude of players with varying backgrounds. Parker Hannifin, for example, recently introduced its first wireless vibration sensors, which are part of an advanced conditioning monitoring system that includes remote monitoring and high-fidelity machine analysis. A Collection Server, which hosts up to six receivers that wirelessly collect data from up to 24 vibration sensors, aggregates data and transmits it into the cloud via cellular or Ethernet technology.

The 90-page Berg report (Industrial Automation and Wireless M2M, available at www.berginsight.com) covers key applications for cellular M2M in industrial automation, an analysis of market developments and interviews with vendors from leading companies. “Advantech, Eaton, Phoenix Contact and Kontron are major providers of industrial automation equipment, and are also important vendors of products featuring embedded cellular connectivity,” says Svanberg. “Moxa, Red Lion, HMS Industrial Networks, B&B Electronics, Westermo and Insys Microelectronics specialize in industrial network equipment including routers, gateways and switches, and also provide products featuring embedded cellular connectivity.”

Digi International, Teltonika, Calamp, Eurotech, Hongdian, Multi-Tech Systems, Maestro Wireless Solutions, Erco & Gener and Robustel Technologies are examples of cellular M2M specialists offering solutions for applications such as fleet management, retail, security as well as industrial automation. eWon, Netmodule, and Viola Systems are examples of vendors with are specialized M2M solutions for industrial applications, says Svanberg.

Sources of cellular technology products and expertise also include the major industrial automation vendors such as ABB, Emerson, Honeywell, Schneider Electric, Siemens and Yokogawa. To help users begin the process of incorporating cellular access points into their networks, Siemens even offered a special tips and tricks session at its 2013 Automation Summit.

Cellular technology is not just for teenagers and texters anymore. It can play an instrumental role in connecting industrial systems and equipment.

RELATED ARTICLES

Whitepaper: Cellular Technology for Remote Monitoring and Alarm Systems

This Moxa whitepaper details how cellular technology can offer the perfect balance of cost effectiveness and simplicity when establishing a connection to a control center for remote monitoring and alarm systems. These basic tips can help you determine how cellular technology might be incorporated into your own remote monitoring project, whether you are establishing the monitoring system for a new site or upgrading the monitoring system for an existing site.

Video: The Coming Era of Smart Devices and the Internet of Things

In this video presentation, Advantech welcomes Harry Forbes, senior analyst with ARC Advisory Group, to discuss the business and technology drivers behind the Internet of Things (IoT). Forbes looks at all the causes of the Internet of Things, as well as market size, applications, industries and business models.

Event: B&B Electronics’ Bill Conley Speaks on Greater M2M Interoperability

Bill Conley, M2M business development manager and wireless expert for B&B Electronics spoke this summer at the M2M Evolution Conference about the oneM2M initiative. The goal of oneM2M is to develop technical specifications that address the need for a common M2M Service Layer that can be readily embedded within hardware and software, and relied on to connect devices in the field with M2M application servers worldwide. A critical objective of oneM2M is to attract and actively involve organizations from M2M-related business domains such as: telematics and intelligent transportation, healthcare, utilities, industrial automation, smart homes, etc. Conley explained that, as it stands today, carriers provide and manage connectivity, hardware vendors build hardware and get it network-ready and certified, and developers and integrators make sure the software works. But looking forward, the range of data streams in M2M combined with the legacy of carrier interfaces points to a need for carriers to provide interoperability and for systems to share information better. The level of complexity in certification and SKU management also needs to be addressed.

About the Author

Renee Bassett

Managing Editor

Leaders relevant to this article: