ASi Updates for Industry’s Digital Age

AS-Interface is one of those industrial technologies that has been such a core part of industry for so long that it’s not often discussed. It’s just one of those key building block technologies used widely in industry.

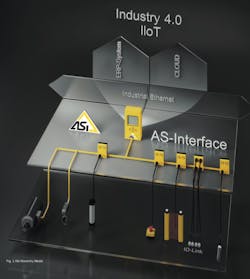

Essentially, it’s an industrial networking technology used to connect field I/O devices (such as actuators, sensors, analog inputs and outputs, push buttons, and valve position sensors) with programmable logic controllers, distributed control systems, and PC-based automation systems. Recognized as an IEC 62026-2 standard technology since 1999, AS-Interface is a topology-free system supported by a several automation technology suppliers.

Like all automation technologies these days, AS-Interface is getting an update for industry’s digital age. The new version of AS-Interface is ASi-5—a single, two-conductor cable that transmits data and energy simultaneously to connect actuators and sensors to higher-level control systems and the cloud.

The new ASi-5 technology and protocol standard are backward compatible with earlier versions of AS-Interface devices and components.

Rolf Becker, CEO of the AS-International Association, says that ASi-5:

- Is a deterministic system with cycle times that are four times shorter than previous ASi versions—1.2 ms for 24 connected devices

- Can handle data widths of 16 bit to 32 bytes per device

- Can run up to 200 meters per segment

- Can handle up to 96 connected devices

- Provides an additional diagnostics channel concurrent to the process data

ASi-5 is also said to offer improved operational performance and maintenance via continuous monitoring of the transmission quality for detailed diagnostics. In addition to single device addressing, devices can be addressed through the ASi-5 master even after installation. The AS-International Association notes that this prevents physically addressing two devices with the same address.

With its ability to transmit energy and data on the same cable, ASi-5 is the only fieldbus system that does not need plug connections to link energy and data, according to the AS-International Association. This means that common cable harnesses in parallel wiring can be replaced by the reverse polarity protected ASi cable, thereby making the system electromagnetically compatible (EMC) without additional cost-intensive shielding.

Integration with other systems, such as IO-Link or HART, remains simple with ASi-5 according to the association. “The host systems simply provide the interfaces, creating multi-point connections. Parameter and diagnostics data can be concurrently transmitted independently from process data—in any amount necessary,” says Becker.

The AS-International Association reports that ASi-5 can be used to integrate safety functions as well, stating: “Safety-critical and conventional applications run on one infrastructure and can be mixed and matched without restrictions, with ASi-5 enabling operation of 96 x 16 safe inputs and outputs.”

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: