Continued Rapid Growth Seen for Industrial Ethernet

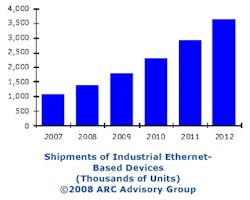

Industrial Ethernet’s migration into the device or input/output (I/O) level of the automation network hierarchy signals its continued march downward in the enterprise architecture. The worldwide market for Ethernet-based devices and I/O is expected to grow at a compound annual growth rate of 27.5 percent over the next five years, says a new study from ARC Advisory Group Inc., Dedham, Mass. The market size totaled more than 1 million nodes in 2007 and is forecast to increase to more than 3 million nodes by 2012, ARC says. Now a staple at the control level of the automation hierarchy, the advent of automation-applicable standards, intelligent implementation strategies, and overall improvements in product reliability have made Ethernet a lead option in even the most demanding motion control applications. Of even greater import as far as growth potential is the market emphasis on Ethernet’s commonality rather than its openness. “Standardization of layers 1 and 2 of the Ethernet stack in IEEE 802.3 makes Commercial Off the Shelf (COTS) physical layer products widely available and familiar to potential OEMs (orginal equipment manufacturers) and end-users, but, as always seems to be the case in the industrial automation segment, each major supplier wants to support their own higher-level protocols,” says ARC Vice President Chantal Polsonetti. “For the customer, this translates to common physical layer components throughout the enterprise, but multiple competing protocols at the automation layer,” notes Polsonetti, the principal author of the new study, titled “Ethernet-based Device Networks Worldwide Outlook.” Commonality benefits Availability of a single network technology that enables vertical integration throughout the enterprise over the same network, at least at the lower tiers of the network stack, is an increasingly compelling value proposition for manufacturers, says the ARC study. Ease of network integration and configuration/reconfiguration, as well as the potential for less expensive, flatter architectures and enterprise-wide data exchange that can be used for multiple purposes ranging from process optimization to asset management are all possible. A common skill base for configuration, installation, maintenance and troubleshooting reduces the need for specialized personnel and allows customers to take advantage of a broader skill base and more readily accessible training and support. Ethernet’s worldwide availability and support by both major information technology (IT) and automation vendors also makes it attractive relative to dedicated industrial networks. Evidence of the reduced emphasis on openness versus commonality in the industrial Ethernet realm is evident in the use of the network in even embedded applications, where proprietary protocols typically reign, ARC says. In the motion control segment for instance, industrial Ethernet is rapidly being adopted in even single-vendor applications that don’t require the ability to plug-and-play components from different suppliers.ARC Advisory Group Inc.www.arcweb.com