Just about any user conference we attend these days has at least some discussion of OPC UA. It has become the go-to standard for open-source software and an important enabler of the interoperability that has become a key talking point for industrial automation and the Industrial Internet of Things (IIoT).

The OPC Foundation has made several partnership announcements over the past couple years, including a connection with Microsoft, FDT’s native integration of OPC UA and many more. Add to that the release last week of the Sercos OPC UA Companion Specification, which describes the mapping of the Sercos device model and the Sercos device profiles to OPC UA so that functions and parameters of Sercos devices are made accessible via OPC UA in a vendor-independent way.

This initiative between Sercos International and the OPC Foundation aims to simplify the communication between machine periphery and supervisory IT systems, and to support the requirements of Industry 4.0 regarding semantic interoperability.

“Sercos provides a very rich, robust device model and device profiles that made logical sense to plug into an OPC UA namespace,” said Thomas Burke, president and executive director of the OPC Foundation. “The Sercos OPC UA Companion Specification enables machine-to-machine interoperability, and machine integration with the cloud-based applications at a minimum. Sercos suppliers will now be able to take advantage of the rich service-oriented architecture of OPC UA, truly facilitating the vision of the embedded world having information integration into the cloud. The OPC community will now be able to easily extend their products to support the great networking technology of Sercos. Both organizations are working together to facilitate and help the suppliers bring certified products to the marketplace supporting this new companion specification.”

Manufacturers are typically faced with integrating and maintaining automation devices and systems from many different suppliers, significantly increasing total cost of ownership (TCO) through the product lifecycle, commented Peter Lutz, managing director of Sercos International. “At the same time, product planning and control require process- and machine-related information to facilitate the efficient use of the manufacturing resources,” he said. “This challenge can be best faced with a standardized mapping which brings together the well-defined semantics of Sercos with the OPC UA Sercos information model.”

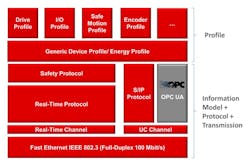

The mapping rules specified by Sercos can be used for different implementation approaches. The OPC UA server functionality can be implemented in a Sercos master device such as CNC or PLC, or it can be transferred to a Sercos slave device. In the latter case, the OPC UA accesses are executed in parallel to the Sercos real-time communication or even without any Sercos real-time communication. Thus, a consistent communication with OPC UA down to the field level is possible without abandoning the hard real-time communication of the Sercos automation bus.

“Use cases cover a broad range from device parametrization and network configuration up to energy management and preventive maintenance,” Lutz said. “Furthermore, new business models can be easily implemented because users and suppliers can rely on a consistent and vendor-independent semantic.”

About the Author

Aaron Hand

Editor-in-Chief, ProFood World

Leaders relevant to this article: