PLM a Mixed Bag to Readers

Product lifecycle management (PLM) software is a relatively new application category. As often happens, early adopters seem to have had widely varying experiences, as this month’s reader survey shows.

About one-third of respondents to the survey indicated a wish to learn more about what PLM was and what it could do for them. Just over two-fifths (44 percent) thought that PLM was a software tool for managing the product design-to-manufacture process, while about 8 percent consider PLM a tool for managing product design.

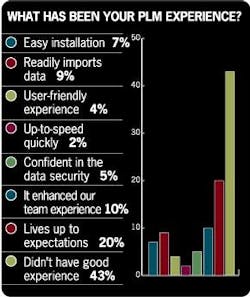

Apparently some early users of PLM software have been less than impressed, but a majority had positive experiences. Forty-three percent of 84 respondents to the survey said they tried it and did not have a good experience. On the other hand, 20 percent said that their implementation lived up to expectations, while another 10 percent reported that PLM software enhanced their team’s experience.

Part of the overall suite of products known as PLM includes software that simulates manufacturing processes. Some software allows designers to build virtual factories while others simulate the workings of the control system—all before anything is actually built. Sixty percent of those responding to the survey are using simulation software, with most (29 percent of the total) using it to simulate their control systems. Thirteen percent use it for process manufacturing, followed by 10 percent who simulate material handling systems. Two percent are modeling their entire manufacturing plants. Of those not using simulation software, two-thirds are considering its use (25 percent of the total response).

For a chance to win a $250 shopping spree at Amazon.com, please take our current online survey on buying automation, by clicking the survey link on our home page, or by clicking here.

If you have an idea for a survey topic, or have a comment about our Web site, please send Editor Gary Mintchell an e-mail at [email protected]