3D Design and Printing for Everyone

Over the past few years, the dramatically lower cost of 3D printing has caused a surge of interest in the technology and the promise it holds for expanding custom manufacturing and whole new industries. Now comes news of a business agreement between MakerBot and Autodesk that brings the promise closer to reality.

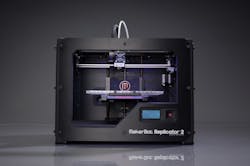

MakerBot, a supplier of desktop 3D printing, and Autodesk, a supplier of 3D design software, have signed a definitive agreement to jointly market a combination of 3D design software and 3D printing hardware to engineers, designers, architects, makers, creators and artists. This collaboration reportedly enables the connection of MakerBot Replicator 2 Desktop 3D Printers with the Autodesk 123D family of apps, making the process of realizing a user’s 3D design through 3D printing on MakerBot Replicator 2 Desktop 3D Printers easier.

The Autodesk 123D family of apps—which includes 123D Catch, 123D Creature, 123D Design and 123D Sculpt—are designed to help users capture, design and make their ideas, as well as connect with other makers around the world for support or inspiration. According to MakerBot, the MakerBot Replicator 2 Desktop 3D Printer “sets a new standard in resolution and accuracy for creating high quality models.”

To give you an idea of the realism of this goal to bring 3D printing/manufacturing to the masses, consider the costs of the products. The MakerBot Replicator 2 sells for $2,199 and the Autodesk apps range in prince from free to $4.99.

Commenting on the partnership between Autodesk and MakerBot, Scott Evans of ARC Advisory Group, said, "This partnership is indicative of the trend towards streamlining art-to-part production, unlocking the potential of 3D printing and opening up new avenues of growth for 3D design software and 3D laser scanning. The goal of the partnership is to eventually create a platform for innovation across multiple levels, from the hobbyist in his/her garage to design professionals.”

This concept of manufacturing coming to the masses via innovations in and accessibility to 3D printing is the main focus of Mitch Free’s upcoming presentation at The Automation Conference. Free, the chairman and CEO of MFG.com, will deliver a keynote presentation on “The Next Industrial Revolution”. His presentation will expand on his inclusion in Chapter 12 (“Factory in the Cloud”) of Chris Anderson’s new book “Makers”. The book explains how a generation of “makers” using the Web’s innovation model will help drive the next big wave in the global economy as the new technologies of digital design, 3D printing and global sourcing gives everyone the power to invent and create products.

To hear Free’s presentation and meet him in person, sign up now to attend The Automation Conference in Chicago, May 14-15, 2013.