With oil and gas, power, process and mining industries experiencing an upsurge, new plants are being designed and built. Three-dimensional modeling software for plant design has been around for a number of years, but the desire for mobile access to those designs hadn’t quite caught up. Now, mobile technologies are improving project access for design decision makers, and the enhanced communication among project team members is saving time and reducing design rework.

According to industry analyst Tony Christian from Cambashi, “For years, full exploitation of the 3D plant model has been hindered by limitations in IT infrastructures, so that Aveva had to develop its leading-edge 3D plant design technology to overcome those limitations.”

Aveva, a global provider of plant modeling, training and IT software, has long been known for its efficient 3D model manipulation. “And today’s near-commoditized high-performance tablet technology has enabled Aveva to deliver a breakthrough,” said Christian.

Aveva’s new mobile app, Aveva E3D Insight, can be used as “a serious productivity tool for plant design projects,” said Bruce Douglas, senior vice president of EDS Strategy & Marketing for Aveva. “Industry research tells us that between 5 and 15 percent of a lead designer’s productive project time can be lost when they are unavailable to make pressing decisions. That is the equivalent of losing a critical-path resource for up to three working days every month. With today’s technology, there is no reason why this should be the case,” he said.

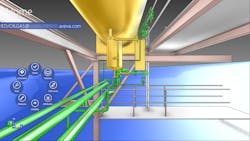

The Windows 8.1 app enables project decision makers in the power, process plant and mining industries to view and approve Aveva Everything 3D designs from a touch-enabled device such as a mobile tablet. It allows a direct collaboration (in the form of commenting) between plant designers in the office using their desktop products and mobile workers using a tablet.

Christian calls E3D “a huge step forward in the reach, accessibility and usability of 3D plant information” because it can handle the large models required by owner operators, EPCs and main automation contractors (MACs).

In December, Aveva announced that EMS-Chemie had moved to Aveva E3D software for the design of its chemical facilities. “We switched over right in the middle of an ongoing project,” said Marco Derungs, Aveva E3D administrator for EMS-Services. The EMS-Services business unit of EMS-Chemie has successfully used Aveva PDMS since 2004.

“Aveva E3D can be mastered quickly and the migration to productive operation took place rapidly,” said Derungs. “This smooth transition was due to the fact that Aveva E3D and Aveva PDMS are fully compatible and can be used simultaneously across the same project.”

“The ability to automatically generate design drawings directly from the 3D model is a critical deliverable for EMS-Services,” explained Helmut Schuller, Aveva executive vice president EMEA. “For other customers it may be the direct integration of as-built information in the form of 3D laser scans” that makes the product useful.

Aveva will be demonstrating Aveva E3D Insight and another product, Aveva Activity Visualisation Platform (AVEVA AVP) at the ARC World Industry Forum in Orlando, Florida, 10-13 February, 2014. Aveva AVP uses advanced Industrial Gaming technology to create an immersive plant simulation environment that enables improved operational safety and efficiency through more effective personnel training. For more information about ARC World Industry Forum, visit ARC World Industry Forum 2014 .

For more information and to download the business paper about Aveva E3d Insight, visit the ‘The Future of Plant Design’ website or contact Avevaon [email protected]