3D Printing as a Service Bureau Tool for Manufacturers

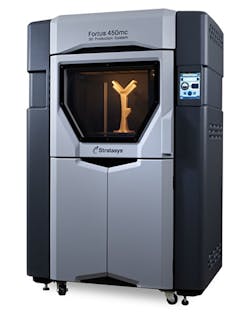

Though the Internet of Things has captured the lion’s share of new technology interest from manufacturersover the past couple of years, 3D printing continues its advance into the industry. A prime example of this is the decision by the Specialty Equipment Market Association (SEMA) Garage to purchase a Stratasys Fortus 450mc 3D printer to give its members the ability to build large prototype and production parts using a range of thermoplastics. SEMA Garage says this service will save its manufacturing members significant amounts of time and reduce the costs associated with bringing new products to market.

SEMA Garage, with more than 6,600 members (including manufacturers, distributors, retailers, auto restorers, car clubs, and race teams), offers a variety of business tools and resources to give its member businesses access to the special high-tech tools and equipment they need to get their products — whether a $10 set of replacement wiper blades or a $10,000 engine modification — off the drawing board and into customer hands.

Covering 15,000 square feet and filled with nearly $2 million of equipment, the SEMA Garage includes two vehicle lifts, a temperature controlled emissions lab, a portable coordinate measuring machine (CMM) for 3D scanning, digital race car scales for precise vehicle weight measurements, and a dynamometer for power output measurements. The addition of the Fortus 3D printer gives the service bureau the ability to manufacture prototype and production parts, and related accessories.

Recent Automation World 3D Printing Coverage