Nissan’s New Approach to Vehicle Design Engineering

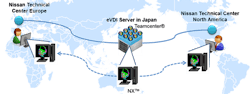

At the center of what Nissan Motor Co. is calling the industry’s first next-generation vehicle design infrastructure is a means of connecting the company’s global R&D centers with a continuous, high-speed connection to its latest vehicle development data. Known as the engineering virtual desktop infrastructure (VDI), Nissan plans to use it to provide for more flexibility and manageability of its global vehicle design operations. Nissan has already begun using the infrastructure in North America and Europe.

According to Nissan, the engineering VDI allows engineers to access a virtual 3D CAD workstation hosted on remote servers and control the workstation on a desktop environment. The VDI enables Nissan to store the latest data on its servers so that teams around the world can access it at any time. The company says that, beyond enhancing productivity, it expects the VDI to also improve cost efficiencies and disaster risk management.

Hewlett Packard Enterprise (HPE) initially proposed the engineering VDI to Nissan. Project teams across Japan, the United States, and Europe were used to deploy, verify, and test the VDI. The system includes:

- Siemens’ NX computer-aided design (CAD) software used throughout the engineering and development of Nissan’s vehicles;

- Siemens’ Teamcenter software serves as the digital backbone for Nissan’s VDI by providing a central product data management system accessible to all appropriate personnel;

- HPE ProLiant WS460c Graphics Server Blades, which provide engineers with a centralized, virtualized desktop, including support for 3D graphics applications;

- HPE 3PAR StoreServ 7400 Storage for data management via a single, scalable Tier-1 storage platform;

- HPE Systems Insight Manager for management of Nissan’s IT infrastructure; and

- Citrix XenDesktop Desktop Virtualization Technology.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: