Seven Ways to Increase Efficiency with Networked Machine Safety

Traditionally, safety circuits were independent of the network. This was deemed the fastest, least complex and most reliable way to implement safe function. Isolated circuits working alongside the machine were the norm. The load on these safety circuits are always a consideration because too many components feeding off the logic element could result in a reduction of the safety category.

· Problem 1—No Diagnostics: Much like collective wiring in a plant, traditional safety circuits offered little value in diagnostics and the ability to gather information on the production process was lost. Anytime a light curtain was breached, or an e-stop button was pushed, production was halted. There is a huge missed opportunity to truly understand the production process and its inefficiencies. Lost is the ability to reduce production costs by understanding the problems that slow down production. Without diagnostic capabilities these events were not typically captured or recorded.

· Problem 2—Tampering: Early safety products often were designed in such a way that tampering would be possible. Tampering and dismantling resulted from “inconvenience,” such as relays wired into safety circuits for ease of reset, tape covering a light curtain to eliminate the burden of shutdown, and physical guards removed and set aside. Tampering not only diminished the ability to collect diagnostics, but severely impeded the overall value of the independent systems to reduce injuries.

· Problem 3—Modern technology demands a better way: Adoption of safety networks is low but growing quickly. Largely driven by European standards, safety on the network is growing in popularity, and, as global standards have become more harmonized, the demand continues to increase. There are currently more than 20 Industrial Ethernet protocols today and several safety protocols (such as PROFIsafe, CIPsafe, AS-i) and that number is growing. Getting safety on the network provides the ability to capture and record the function of that safety circuit and it offers immeasurable value in improving efficiency, gaining a competitive advantage and reducing or eliminating injury. Understanding safety means fully understanding the process on the machine with full transparency.

Seven ways to increase efficiency and gain a competitive advantage:

1. A changing mindset about safety has led to a different opinion in industry about just how valuable safety can be. It’s not just socially responsible. Increased safety is now viewed as a significant competitive advantage. This can often make a difference for retention of skilled labor.

2. The enhanced availability of safety rated products allows machine builders to obtain the appropriate category rated safety with fewer components, less wiring and easier installation. Finding safety standard compliant safety products—such as the P33 Safety Exhaust Valve product offered by Parker—take away the safety guesswork when shipping a machine.

3. The availability of a broader range of network safe products. The continued development of PROFISafe and CIPsafe products have driven down pricing making adoption more feasible for many facilities who previously may have had small budgets dedicated to safety.

4. Ethernet based safety protocols utilize the same wiring for the safety data that is used for logic (in one wire channel). This provides the user with improved awareness of the entire system’s functions while reducing the footprint of the safety circuit used in traditional safety circuits.

5. The integration of safety diagnostics allows the machine builder to quickly determine the faulted component or wiring errors for faster commissioning of the machine and troubleshooting.

6. Network safety creates a stop in a controlled manner and does not need to power off the machine when in a safe state. Since the machine does not need to stop abruptly and be powered-up again to restart production, cycle time is enhanced, and scrap is reduced.

7. Decentralized safe I/O is growing in popularity. An advantage of having remote I/O is that the I/O can be either safe I/O or standard I/O on the remote module similar to the valve driver on a valve manifold, making it easier to start-up and reducing labor costs.

The goal is to increase safety and prevent personal injury. In addition to preventing personal injury, safety done right can also lead to many other advantages such as: reduced costs for time saved, fewer components used and space saved. While safety over the network streamlines shop floor operations, it also adds a layer of transparency to safe function and machine operation while increasing efficiency.

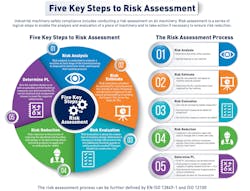

The competitive advantages become clear quickly: a hazard on a machine presents a risk, a risk will often result in an injury. Following the steps to risk assessment the first requirement is to design risk out of the machine where possible. Where designing out risk is not possible and safety products must be implemented important consideration must be made on best methods of implementation (including placing those products directly on the network).

As safer technologies advance and safety becomes an integral part of machinery design with network integration, there will be less opportunity for ongoing errors, and, better fault detection thereby reducing those risks. Fixing the root cause of the safety issue will equal an improved and more efficient process for the long term. Measuring inefficiencies and implementing change means a more efficient, safer and productive work environment.

The steps to risk assessment are still an essential part of machine design regardless of how safety circuits are connected. Following the machinery directives ensure risk assessment is done and networking safety will help optimize efficiency and reduce costs.

About the Author

Linda Caron, CSME

Global Product Manager for Factory Automation, Parker Hannifin

Leaders relevant to this article: