Pozyx Advances Industrial Asset Tracking and Tackles Operational Problems Supporting Industry 4.0 with Unmatched Real-Time Visibility

Pozyx, a leading provider of RTLS (real-time location system) and ART (advanced real-time tracking) solutions, today announced the launch of its new Pozyx software Platform, a future-proof asset tracking and identification solution for seamless indoor and outdoor tracking, based on the omlox hub and supporting multiple location technologies.

The Pozyx Platform is designed for smart manufacturing providing supply chain solutions supporting Industry 4.0. It tracks and identifies any asset providing real-time data to relieve operational pain, improve operational efficiency, enhance productivity, and increase workflow performance. The use cases are defined to bring visibility and valuable insights on WIP, workforce efficiency, supply chain, and space utilization. It facilitates warehouse and inventory control, keeps track of returnable packaging and critical tools and slashes lost asset costs.

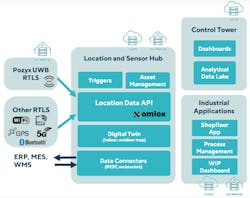

Pozyx is contributing member and early adopter of omlox - the open and internationally recognized standard for Real-Time Location Systems (RTLS) - to achieve the common goal of creating an integrated RTLS technology ecosystem that supports data from different location technologies and interoperability within the UWB based locating zone.

The new Pozyx Platform is based on the omlox hub (*) where location data from UWB, 5G, RFID, WiFi, Bluetooth, and GPS converge. Independent of technology and manufacturer, the data is made available to other applications via standardized APIs. Users and application builders only need to consider a single API and do not have to worry about the underlying technologies used. The platform offers a seamless indoor/outdoor transition with zoom-in from a worldwide map to a detailed indoor map, showing highly accurate locations, up to 10cm precise. It has an open architecture with flexible interfaces for smooth integration with ERP, MES, and WMS. A full set of industry-specific analytics and dashboards make the collected data actionable for operational purposes.