Cornerstone Automation Partners with Richard S. Burns & Company Inc. to Automate Patented Recycling Sortation Process for LEED Compliance

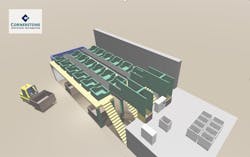

Cornerstone Automation, a leading control system integration company based in Telford, PA, today announced the successful completion of the patented Tommy Cart® sortation solution for Richard S. Burns & Company Inc. Cornerstone’s role in automating their unique process included collaboration on the development of the software and designing and implementing the industrial controls required to manage the sortation of thousands of tons of construction waste and materials a day.

Richard S. Burns & Company Inc. is a complete recycling and waste recovery facility out of Philadelphia, PA. They patented the Tommy Cart® solution, a highly maneuverable and effective alternative to dumpsters to provide a better alternative for loading out debris for any job site.

The Tommy Cart® solution utilizes an automated lift and conveyor sortation system that tracks the collection and weights of all commodities and debris. Their one-of-a-kind process takes the weights of full individual bins of sorted commodities for each individual customer so that they have documentation to prove they are in compliance with LEED Certification requirements. Previous methods to track and weigh materials were not as accurate, and the manual sortation was much more cumbersome.

“Cornerstone goes above and beyond the call of duty,” said Allen Burns, President of Richard S. Burns & Company Inc. “They’re a very resourceful group of people, and they’re very knowledgeable. They bring a lot to the table and the word “resourceful” just continually comes to my mind. Anytime we reach out to them they have an answer whether it’s something to do with our system or how to run better equipment.”

“We were excited to work with Richard S. Burns & Company, Inc. to automate their sortation process and are thrilled with its success,” said Alan Ferrin, President of Cornerstone Automation. “Automating portions of this process makes it more sustainable and efficient. This innovative solution ultimately costs less because it removes so much of the manual process, and is more accurate in terms of reporting than manually sorting all of that material.”