How AI Agents Will Transform MES and Manufacturing

- Manufacturing data platforms form the "holy trinity of smart manufacturing" alongside MES and IoT connectivity, providing the diverse data foundation that AI requires, with MES serving as the foundation for digital twins and contextualizer of IoT data.

- The "adaptation paradox" is accelerating as AI technology evolves exponentially while organizations adapt logarithmically, creating an urgent need for manufacturers to begin AI agent integration now or risk being left behind by competitors who leverage these capabilities for dynamic production optimization and autonomous decision-making.

- Trust and safety in AI-powered manufacturing can be achieved through three complementary approaches: RAG (retrieval augmented generation) to eliminate hallucinations by grounding AI responses in actual MES data, guardrails to set policy boundaries for what agents can do and maintaining humans in the loop with decision trails that explain how AI systems reached their conclusions.

At the heart of every MES lies its data model, but the intelligence layer remains largely static because it’s built on predetermined logic and configurations. This reality means that, while MES software offers extensive possibilities for customization and extensibility, it fundamentally operates on fixed rules in environments that are anything but static.

Expounding on this core aspect of MES technology, Francisco Almada Lobo, CEO and co-founder of Critical Manufacturing, delivered a keynote presentation at the company’s MES & Industry 4.0 Summit to prepare manufacturers for the MES technology changes headed their way.

While the dynamic nature of manufacturing environments is well-recognized, Almada stressed that manufacturing processes themselves are no longer static either. Principal drivers of this change range from global economic issues such as new tariffs and supply chain disruptions to greater demands for product customization.

This creates a mismatch between rigid system logic and fluid manufacturing realities, creating inefficiencies that traditional MES architectures can struggle to address.

The solution, according to Lobo, lies not in replacing MES systems entirely, but in augmenting them with AI agents that can learn, adapt and make intelligent decisions in real-time. However, he noted that success in this transformation requires two critical elements: embracing AI agents as an inevitable reality and developing robust data and architectural strategies to support them.

Kurzweil’s vision and its relevance to manufacturing technology

While the predictions of Ray Kurzweil, the renowned futurist and AI pioneer, may seem superfluous to an MES discussion, a central aspect of his approach to technology centered on its exponential nature. To explain this, Lobo noted that Kurzweil compares technology to gravity — in that it’s an accelerating force.

Agentic AI can start making localized decisions based on machine status conditions to reschedule tasks, adapt to disruptions or optimize production on the fly.

In his 2005 book "The Singularity is Near," Kurzweil noted that $1,000 in computing power could match an insect brain in the early 2000s, but would match a mouse brain by 2010 and, he projected that, by 2050, that same investment could provide computational power equivalent to all human brains combined.

This exponential growth creates what's known as the Martex Law, coined by HubSpot's Scott Brinker. Almada explained this law posits that technology evolves exponentially while organizations evolve, logarithmically, at a much slower pace. The widening gap makes it nearly impossible for average organizations to keep up with technological advancement.

Managing this challenge requires strategic technology adoption, organizational agility and, sometimes, revolutionary thinking, Lobo said. He noted that companies must be prepared to fundamentally reimagine their operations by asking: "If we were starting from scratch today, how would we do it?"

Three waves of AI evolution that matter to manufacturers

The AI transformation now underway in manufacturing unfolds across three distinct but layered waves, each building on the previous one:

Wave One: Classical machine learning emerged around 2007, using techniques like regression, decision trees and clustering on well-defined data structures. Despite being widely available since 2010, many manufacturing companies have yet to fully capitalize on these capabilities.

Wave Two: Large language models started with the 2017 "Attention is All You Need" paper from Google Brain researchers, which introduced the transformer architecture that revolutionized natural language processing. This breakthrough led to systems like GPT-3 in 2020 and ChatGPT in 2022, creating unprecedented capabilities in text generation, problem-solving and programming.

Wave Three: AI Agents represent the current frontier, promising to transform manufacturing operations fundamentally, according to Almada. “Unlike their predecessors, AI agents don't simply follow instructions — they reason, plan and execute complex tasks autonomously,” he said.

The data platform foundation

The gap between most modern manufacturing technologies and AI-enabled technologies is that traditional, transactional manufacturing systems using relational databases were never designed for AI workloads, which require massive, diverse datasets spanning images, text, logs and sensor feeds. AI also needs historical data and access to live stream processing data for real-time responses.

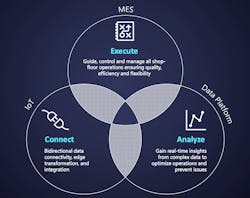

This need for a variety of data sources has given birth to a new category of systems called manufacturing data platforms, said Lobo. “These platforms, together with MES and IoT connectivity, are what I call the ‘holy trinity of smart manufacturing.’”

To better understand this, consider that IoT data compiled from multiple sensors and devices across a manufacturing facility needs MES for contextualization and to deal with critical aspects like timestamp synchronization.

“You can’t do this with a data lake of enterprise level data,” said Lobo. “What we are proposing is to use the basic structure of MES as the basis of a model that allows companies to start using AI models effectively from day one. I say this because MES is probably one of the most powerful foundations for a digital twin.”

Developing trust with LLMs

We all know that LLMs can “hallucinate” or make up responses on the fly and that LLMs can forget key information between uses. Considering this, Lobo said many people have asked him why he contends that LLMs should be used as a key aspect in the brain of an MES.

“One technique that gets us past the hallucinations issue with LLMs,” Lobo said, “is called RAG — retrieval, augmented generation. With this, we can embed our MES knowledge base so that the AI, using RAG, queries this data and provides the context for the LLM to understand it and come up with a response.”

Another technique is called fine tuning. Lobo contends that this a great way to provide additional context for AI. “Here, we take a pre-trained LLM model and we train it further on a specific data set to adapt it to a particular domain,” he said.

The gap between most modern manufacturing technologies and AI-enabled technologies is that traditional, transactional manufacturing systems using relational databases were never designed for AI workloads.

A third way is through prompt engineering. “With this, we can design our input text to strategically steer the outputs of the LLM by addressing phrasing structure and interacting with it in a way that will lead it to produce the results we want,” said Lobo.

The agent architecture revolution

With these AI tools and approaches now widely available, Lobo explained how Critical Manufacturing is working to make MES data available for the AI agents to use.

“This process was incredibly difficult before Anthropic released the model context protocol, or MCP, in November 2024,” he said. “The MCP was designed to standardize how LLMs connect to external tools. Although the LLM only generates text, this text can provide instructions for an MCP client to access a server and retrieve data from an API connected to the MES. This brings the full power of an MES to the AI agents so that the LLM starts becoming more of a brain.”

With this capability, agentic AI can start making localized decisions based on machine status conditions to reschedule tasks, adapt to disruptions or optimize production on the fly, he explained.

The next step involves getting these AI agents to work together when needed. Google recently developed a new protocol for this called Agent-to-Agent which allows the agents to talk to each other using the protocol.

“It's likely that, for very complex cases, we’ll start having agents that are, what we call, meta agents,” Lobo said. “So, imagine an MES with its user interface and business rules. And then you plug in a team of agents. These meta agents will be able to look into what's happening in your system and start coming up with recommendations for a human to approve. A key thing to realize here is that there's memory associated with this. This memory creates a continuous flywheel of learning. As the agent offers suggestions and the human decides to approve them or not, the AI will assess the effectiveness of the result and will learn based on that. Its memory adjusts to behavior. And so, with every cycle, the agent becomes smarter and smarter as it goes.”

Safety considerations

Of course, one of the biggest concerns about using AI for critical decision making in manufacturing is to ensure safety mechanisms are in place. To address this, Lobo pointed out three available methods:

- Guardrails, which are essentially policy boundaries. They define what the agent can or cannot do. These guardrails can be safety-related, compliance-related or tied to operational limits.

- Keep a “human in the loop” who has responsibility for what the agent does or doesn't do.

- Implement decision trails to explain how the LLM came up with the result.

The adaptation paradox

The current pace of AI development creates what's being called the "adaptation paradox," i.e., as technology becomes more sophisticated, organizations have less time to learn and implement them. If you haven’t been keeping track, consider the rapid pace of development in the LLM space: ChatGPT was publicly released in November 2022. This was followed by large reasoning models in late 2023, MCP in November 2024 and agent-to-agent protocols in April 2025.

“This acceleration means manufacturing organizations must begin preparing now for AI agent integration,” Lobo said. “Those who delay risk being left behind as competitors leverage these capabilities for dynamic production optimization, intelligent exception handling and autonomous decision-making.”

Lobo noted that Critical Manufacturing is accelerating its work with these technologies because “this will affect all of us,” he said, adding one of W. Edwards Deming’s better-known quotes to support his reasoning: ‘It's not necessary to change. Survival is not mandatory.’

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: