How to Integrate Decades-Old Modbus Devices Without Regret

Key Highlights

- Modbus remains widely used in industrial settings and the market is expected to grow from $1.2 billion to $2.5 billion by 2033, making it far from obsolete despite being an older protocol with no built-in security features.

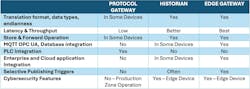

- Three main architectures are recommended for integrating Modbus networks in 2026: protocol gateways for moving data into PLCs, historians for archiving data for maintenance and compliance, and edge gateways for publishing data to enterprise and cloud applications.

- Critical best practices include maintaining comprehensive documentation of all Modbus devices and registers, using dedicated gateway devices rather than embedding Modbus logic in PLCs, and planning for eventual migration to more modern devices with better security and connectivity.

Modbus remains the most common language for industrial data and the simplest communication protocol to add to the drives, meters, power analyzers, weigh scales and specialty instrumentation found in every kind of process and discrete manufacturing plant. OEMs and vendors alike know that supporting Modbus provides a long-lasting communication protocol that is both inexpensive and universally supported.

Conceived during an era prior to common factory floor device communications, Modbus arrived on the scene when PLCs used chassis-based I/O. Though Modbus has survived the transition to multi-vendor, multi-network and data-hungry PLCs, HMIs and SCADA systems, it has not evolved, yet it continues to thrive.

A primary reason Modbus systems haven’t been replaced is that upgrading and replacing these systems can be expensive with little return on investment. Essentially, the rip and replace method almost always costs more than simply integrating Modbus data from your legacy device into your updated control system or enterprise application.

Plus, integrating Modbus into modern systems isn’t expensive. Modbus gateways from HMS, Moxa or Real Time Automation avoid the downtime, equipment costs and the significant labor of more functional and complex higher-end instrumentation.

Though some contend that Modbus has become obsolete in today’s automation landscape, data indicates that not only isn’t Modbus obsolete, the Modbus market is expanding. A study from FutureBytes Labs, “Exploring the Dynamics of Modbus Communication Module Market: Key Insights and Trends for 2033,” indicates that the Modbus market isn’t shrinking and is expected to grow from $1.2 to $2.5 billion over the next 7 years.

Can Modbus networks be secured?

Modbus networks can be secured at the Modbus master and client devices — the devices that interface Modbus networks to the outside world. Modbus itself was never designed to be secure, as it has no authentication, encryption or access control.

Use a protocol gateway when you need to move Modbus data into a PLC or other local device within the production zone. Never use a protocol gateway to deliver data outside a production zone.

Modbus TCP and RTU networks do provide a measure of security due to the Modbus architecture. A Modbus RTU slave or TCP server device only transmits on request and only transmits data values with no ability to message the client/master or any other device. When compromised, the threat exposure varies with how well the system is segmented, what application the data influences and what other Modbus devices can be reached from the compromised device.

With that said, cybersecurity threats are more pervasive and serious in the devices that collect and manipulate Modbus data. Those PLCs, servers, HMIs, gateways and other devices have a larger threat footprint and are cybersecurity concerns, whether data is collected from Modbus TCP servers or RTU slaves.

Six rules for integrating Modbus networks in 2026

Your Modbus networks contain valuable data that is likely not critical to your control loops but important to your overall operation. These valuable data points include pressures, levels, flows, vibrations, energy and other data associated with the operation of your production systems.

Making that data available to your PLC logic, SCADA system or enterprise applications is important for monitoring in-plant utilities, such as water, air and power. This legacy data has value when contextualized correctly.

Historians collect, normalize, contextualize and archive Modbus data before enterprise or cloud systems touch it. Archived Modbus data is useful for later diagnosis, analysis or transfer to long-term storage.

With the importance of these data points in mind, following are six important rules for integrating Modbus network data into your operations network:

- Identify which data (temperature, speed, energy, pressure) is available, the destination for it and the format that best suits the receiving application. Collect and transmit data you may not need today; it’s essentially free, and you’ll likely find a use for it in the future.

- Exclude control data from Modbus unless your PLC can act as a Modbus RTU master or TCP client. Control system data should be on faster, more highly integrated networks like EtherNet/IP or Profinet.

- For maximum maintainability and troubleshooting, use a single device to collect and format Modbus data. This isn’t an issue with Modbus RTU, as it can only have one master. But on Modbus TCP, which supports multiple clients, there should only be one client device connected to a Modbus server device.

- Use a gateway or interface device to convert and type the data for easier ingestion by a receiver. Modbus devices are notorious for overlaying types on unsigned integer registers (i.e., four registers forming a floating-point value). PLCs are not where you want these translations to occur.

- Realize that, as Modbus devices reach obsolescence, the vendors are likely to replace them with advanced security and network communications. Design your network to accommodate Ethernet capable devices in the future.

- Collect and store Modbus device documentation for each device on the Modbus network. Create a map of the available registers and coils along with any overlaid data formats. This information is vital for future troubleshooting.

3 Modbus network integration architectures

In 2026, there are three typical architectures for integrating Modbus networks: Protocol gateways that provide integration with PLCs; historians that archive Modbus data for maintenance, troubleshooting and compliance; and edge gateways that provide integration with enterprise and cloud applications.

Integration architecture 1: Protocol gateway

Using a protocol gateway to move Modbus data from Modbus TCP or Modbus RTU devices to your PLC is the least bad way to integrate Modbus into an Allen-Bradley system in 2026. However, it is not a substitute for native control networks, good architecture or clear data ownership.

Advantages of this architecture include:

- Modbus devices appear to the PLC as standard EtherNet/IP or Profinet end-devices.

- No special ladder logic required. Modbus data is indistinguishable from EtherNet/IP and Profinet network data.

- The Modbus RTU or TCP network interface is managed by the protocol gateway.

- Modbus gateways provide endianness (the order in which bytes are arranged within larger data types in computer memory), format and type conversions that the PLC can easily ingest data with appropriate, well-known and supported data types.

- The protocol gateway provides troubleshooting diagnostics and long-term maintainability.

Limitations of this architecture include:

- Modbus update rates through the gateway are slower and less predictable than native EtherNet/IP inputs and outputs.

- There are cybersecurity limitations. Not all protocol gateways use secure interfaces and not all securely interact with a PLC, such as EtherNet/IP CIP Security.

- Protocol gateways are a single point of failure for the Modbus network connection.

- Throughput can be limited and non-linear, especially when large numbers of devices or large amounts of data are transferred.

Integration architecture 2: Historian

A historian saves data from your Modbus devices in a time-series database. Historians collect, normalize, contextualize and archive Modbus data before enterprise or cloud systems touch it. Archived Modbus data is useful for later diagnosis, analysis or transfer to long-term storage.

Collect and store Modbus device documentation for each device on the Modbus network. Create a map of the available registers and coils along with any overlaid data formats. This information is vital for future troubleshooting.

Advantages of this architecture include:

- Publishing flexibility: A select history of Modbus data values can be published when needed.

- Contextualization: Data from multiple Modbus devices can be combined and modeled to create context for enterprise and cloud applications.

- Selective triggering: Modbus data can be transmitted to enterprise and cloud applications on a timed basis or on change of value using standard IT protocols.

- Data transformations: Clean Modbus data can be generated by converting, reformatting and programmatically transforming data as needed for upstream applications. Limitations of this architecture include:

- A historian timestamps on data arrival, not when the Modbus data read occurred.

- Update rates aren’t fixed as polling cycles may change significantly when new devices are added, or additional data is added to the polling cycle.

- Users must manually ensure that scaling, data types and endianness are correct to prevent archiving of incorrect data values.

- Storing Modbus data does not modernize the device or system. Legacy constraints still shape analytics. Cloud access amplifies, not fixes, inconsistent data.

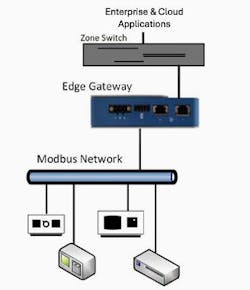

Integration architecture 3: Edge gateway

An Edge gateway publishes your Modbus data to time-series databases, SCADA systems, maintenance applications and other enterprise and cloud applications. Edge gateways are designed for both security and publishing flexibility. The ability to do rule-based publishing and use a variety of IT protocols makes edge gateways valuable, but they are not a way to escape Modbus’s structural limits. Use them to isolate, normalize and control data flow, but do not expect them to turn legacy devices into event-driven, high-fidelity data sources.

Advantages of this architecture include those mentioned for Modbus historians, but also include:

- Lower latency: Edge gateways are generally more powerful devices than protocol gateways and don’t have the database overhead. Data can be published more quickly in an edge gateway.

- Cybersecurity: Edge gateways live on the edge and cybersecurity is a top design requirement.

- Publishing flexibility: Edge gateways support a wide variety of publishing mechanisms, including REST, MQTT, OPC UA, direct database integration and more. Limitations of this architecture include those mentioned for Modbus historians, as well as:

- Edge gateway resources are finite. A heavy load of databases and applications requiring data can create a system choke point.

- Edge gateways can only encrypt and protect the values that are collected from the unsecured and unencrypted Modbus traffic. Modbus can be isolated by an edge gateway but not secured.

- Because Modbus data is being published on modern IT protocols, it appears to be “modern,” but the data is still legacy data from legacy devices and should be treated as such. When to use a protocol gateway, historian or edge gateway? Protocol gateways, historians and edge gateways each have a unique place in automation architectures in 2026.

My recommendations are to:

- Use a protocol gateway when you need to move Modbus data into a PLC or other local device within the production zone. Never use a protocol gateway to deliver data outside a production zone.

- Use a historian when archiving Modbus data required for maintenance, troubleshooting or long-term compliance archives.

- Use an edge gateway when moving Modbus data outside the production zone and data archiving is not required.

Though Modbus has survived the transition to multi-vendor, multi-network and data-hungry PLCs, HMIs and SCADA systems, it has not evolved, yet it continues to thrive.

What to avoid when integrating Modbus networks

Some of the potential problems, in priority order, are:

- Missing documentation. Legacy devices, designed and built before the Internet can be very difficult to find. Without the right documentation, it’s impossible to know what data is available and how it is formatted.

- Register alignment, scaling and endianness issues. This goes with lack of proper documentation. Document the endianness, format and units for every register in your process. Know the destination of that data and if the value must be converted and retyped for the destination application. This is especially important when moving Modbus data into a PLC.

- Termination and wiring with Modbus RTU. Failed terminations, missing terminating resistors and the wrong wiring has doomed many a Modbus project. Inspecting, tightening and verifying terminating resistors pays huge dividends.

- Polling rates vs. device response limits. You may configure your Modbus master or client to poll every 20 msec, but if you have several devices that take 100 msec to respond, your data ingestion will be different from what you’ve planned.

- Embedding Modbus logic deep in PLC programs. PLCs are not protocol gateways, making this action an insidious mistake. Control logic updates can change how your Modbus network is polled. Modbus logic updates can alter your control logic. Maintainability is often severely compromised when using Modbus out of a PLC.

- No diagnostics. Not having a diagnostic process in place severely inhibits troubleshooting. Make sure your Modbus master or client (protocol gateway, historian or edge gateway) provides diagnostic data when data goes missing.

- Troubleshooting tools. There are lots of Modbus analyzers, protocol diagnostic tools and simulators available. Have one or more of them ready to go when a problem strikes.

- Vendor-specific function code behavior. Some Modbus vendors have adopted non-standard function codes, register formats, bit configurations and other features. Verify that your Modbus master or client can use those function codes or data formats.

- Treating Modbus as being temporary for years. Modbus devices work and have valuable data. That does not mean that they should be in your system 10 years from now. Over time, move to meters, scales and other devices that offer greater connectivity and easier integration.

More industrial networking insights from Automation World:

About the Author

John Rinaldi

John Rinaldi is chief strategist and director of creating WOW! for Real Time Automation (RTA) in Pewaukee, Wis. John is not only a recognized expert in industrial networks and an automation strategist but a speaker, blogger, the author of more than 100 articles on industrial networking, and six books, including Industrial Ethernet, OPC UA: The Basics, Modbus, OPC UA - The Everyman's Guide and Ethernet/IP.