What’s Driving the Next Stage of HMI/SCADA Development?

Why this article is worth your time:

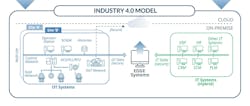

- Manufacturers are adopting hybrid models that combine on-premises edge computing for real-time control with cloud services for historical data storage and advanced analytics, supported by open communication standards like MQTT and OPC UA that enable vendor-neutral data exchange.

- Smart sensors, energy meters and wireless transmitters are being widely integrated into HMI/SCADA platforms, enabling real-time equipment monitoring and predictive maintenance through temperature and vibration data that can detect anomalies before they cause costly downtime.

- HMIs are evolving to resemble familiar consumer devices with touchscreen interfaces, gesture controls and voice commands, while AI applications for predictive maintenance and anomaly detection are beginning to emerge.

As computing and communications technologies progress, they have a way of changing the look and feel of the devices and processes that use them. Human-machine interfaces (HMIs) and supervisory control and data acquisition (SCADA) technologies are, of course, no exception.

“Among the most important trends in industrial automation today is the integration of IIoT devices into SCADA systems and HMIs,” said Silvia Gonzalez, director of controls, software and intelligent automation at Emerson. “We’re seeing widespread use of smart sensors, energy meters and wireless transmitters feeding data directly into HMI/SCADA platforms. It’s a shift that is fundamentally transforming how operations are monitored, visualized and optimized.”

These IIoT devices are generating vast amounts of data, leading to a “need for robust and reliable industrial computing platforms to aggregate, process and visualize this information at the edge,” said David Zhu-Grant, director of product management at OnLogic. “By pulling sensor data and analytics closer to where the HMI runtime is located, manufacturing organizations can reduce latency in decision-making and lower overall system costs.”

Some of the more common IIoT device integrations with HMI/SCADA involve the use of temperature and vibration sensors attached to equipment and transmitting their data to an HMI. With this information, the equipment anomalies can be more easily detected before they lead to downtime.

Hybrid edge-cloud architectures

Another HMI/SCADA trend is a rising connection to the cloud. “Although the conversation around cloud-based SCADA has gained significant traction, the actual shift from traditional on-premises systems has been more evolutionary than revolutionary,” said Zhu-Grant. “Industries with stringent security requirements, low-latency needs or well-established infrastructure will often maintain their core SCADA functionalities on-premises.”

More experimental, but rapidly evolving technologies, include voice-controlled HMIs, gesture interfaces and augmented-reality overlays.

For this reason, much of the gradual evolution toward cloud-based SCADA has resulted in hybrid architectures. “In this model, edge computing platforms handle real-time control and data acquisition locally,” explained Zhu-Grant. Meanwhile, cloud services are used for storing historical data, performing advanced analytics and monitoring processes remotely.

In these hybrid architectures, the use of containers enables users to scale from on-premises applications out to the cloud. “This strategy allows manufacturers to harness the scalability and accessibility of the cloud, yet retain the reliability, performance and security required for critical control functions at the edge or on-site,” he says. Benefits include better data accessibility, enhanced collaboration and access to cloud-based analytics tools.

Some automation vendors also talk about a two-cloud approach — one public and one private. “Many manufacturing organizations adopt hybrid models that combine the security and control of private, on-premises clouds with the flexibility, scalability and remote accessibility of public cloud platforms,” adds Karthik Gopalakrishnan, solutions consultant at Yokogawa.

For an example of technology that supports integrating cloud environments with SCADA, Gopalakrishnan pointed to Yokogawa’s CI Server. “This type of hybrid architecture provides secure, low-latency data communication between private and public clouds,” he said. “It ensures that critical process control remains robust and provides global access to operational data.”

The impact of unified namespace (UNS)

A parallel development supporting edge-to-cloud architectures has been the trend to replace proprietary or legacy protocols with open communication standards like MQTT and OPC UA. “These standards enable the exchange of scalable, vendor-neutral data and support for modern integration patterns such as publish-subscribe messaging,” said Gonzalez. “These patterns are essential for managing the complexity of growing device networks.”

We have seen AI being used in predictive maintenance and anomaly detection, but not as much in process evaluation.

Another approach gaining traction in edge-to-cloud architectures is unified namespace (UNS), a standardized way to name, organize and access real-time data across an enterprise. “IIoT data is increasingly contextualized at the edge, structured into a UNS, and shared upward with cloud-based SCADA and analytics, such as those offered on Aveva Connect,” explained John Krajewski, vice president of product management—operations control at Aveva.

“The rise of UNS enables all IIoT devices, SCADA systems, MES and cloud analytics tools to publish and subscribe to a single, centralized real-time data model,” he added. This means that operations, IT and engineering can all access the same real-time data in context.

HMI/SCADA poised for increased use of AI

To date, artificial intelligence has not been widely used in day-to-day SCADA applications. “We have seen AI being used in predictive maintenance and anomaly detection,” said Ramey Miller, HMI product portfolio manager at Siemens, “but not as much in process evaluation.”

However, some automation companies are beginning to incorporate computing power capable of supporting AI applications. For example, HMIs are being developed with on-device AI inference, adaptive user interfaces and context-aware content delivery.

Although AI has largely been proliferating in SCADA analytics applications, Yokogawa has gone a step further to incorporate it into closed-loop system using its Factorial Kernel Dynamic Policy Programing. “This is a reinforcement AI methodology for solving specific process issues where PID and APC (advanced process control) have been considered but found lacking,” said Anu Mahesh, product and industry marketing specialist at Yokogawa. These types of AI technologies will sit on top of SCADA or distributed control systems (DCSs).

Despite the benefits that AI can offer, especially for SCADA-driven analytics, adoption in discrete manufacturing has been slow. “In our experience, most companies are not yet actively implementing AI in their SCADA environments, nor is it a frequent topic in discussions with customers,” said Danny Andree, a sales engineer at Emerson. “Although interest is high, actual implementation is still confined to pilots and isolated use cases, mostly within large enterprises.”

Challenges such as fragmented data, legacy infrastructure, buy-in from operators, unclear ROI and limited in-house AI expertise are slowing widespread adoption. Even so, Andree said to say tuned. “Momentum is building. The next few years will likely determine how quickly these technologies move from concept to standard practice.”

HMIs become more like smartphones

Yet another trend in HMI/SCADA has been a continued evolution in the design of the HMI itself. “A primary driver has been to make the interface more familiar to users by making it more like their everyday devices — that is, more like their tablets and cell phones,” said Miller. The goal is for the familiarity and intuitiveness of the design to help users to feel comfortable using the HMI and streamline training for new workers.

By pulling sensor data and analytics closer to where the HMI runtime is located, manufacturing organizations can reduce latency in decision-making and lower overall system costs.

“Touchscreen interfaces have become standard, replacing physical buttons with high-resolution, multi-touch panels that enable faster interaction and greater flexibility,” added Andree. This allows users to interact with the HMI through touch gestures like swiping and pinching on the touch screen.

“More experimental, but rapidly evolving technologies, include voice-controlled HMIs, gesture interfaces and augmented-reality overlays,” said Andree. These largely experimental approaches permit hands-free interaction and promote safety.

“Voice-based commands and hands-free gesture control are emerging in high-safety or mobile operations,” added Krajewski. “But they are not yet widespread in industrial settings.”

Meanwhile, the screens themselves have been evolving, too. “High-resolution projected capacitive touchscreens with optical bonding and wet tracking capability are becoming standard,” said Zhu-Grant, along with the use of larger screens to allow visualization of more complex datasets with brighter backgrounds to enhance readability in bright light environments.

More HMI/SCADA insights from Automation World:

About the Author

James R. Koelsch, contributing writer

Contributing Editor

Leaders relevant to this article: