Inductive Automation's Platform Evolves to Address Industry’s Biggest Challenges

- What began as a basic OPC-to-SQL utility has grown into an open industrial integration platform designed to break data silos and overcome the limitations of the traditional automation pyramid.

- Ignition’s architecture, supporting IIoT concepts and MQTT, fulfills the Industry 4.0 vision by enabling vertical and horizontal integration across plants, sites and enterprise systems.

- Solution Suites are introduced — curated sets of Ignition modules built around some of Ignition’s most popular use cases.

In the early 2000s, a frustrated system integrator named Steve Hechtman looked at the industrial software landscape and saw limitations everywhere he turned. The existing tools were rigid, expensive and seemed designed more to lock customers into vendor ecosystems than solve real operational challenges. From that frustration emerged what would become the Ignition platform.

"23 years ago, we were introduced to Steve Hechtman (founder of Inductive Automation), a systems integrator who was frustrated with the options available to him in the industrial software market, and who had ideas for a better way to make OT (operational technology) software," said Carl Gould, chief technology officer at Inductive Automation, reflecting on the company's origins at the recent Ignition 8.3 launch during the company’s Ignition Community Conference.

What started as a simple utility connecting OPC to SQL databases in 2003 has evolved into what Gould described as "a modern, sleek and capable industrial integration platform that's able to span horizontally across many different industries and deeply within your industrial organizations."

Colby Clegg, CEO of Inductive Automation, noted that Ignition’s journey from utility to platform represents more than just product evolution — it’s part of a fundamental shift in how industrial enterprises approach integration and data management.

Building beyond the traditional automation pyramid

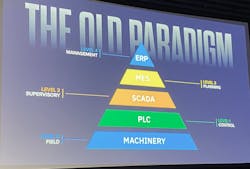

For decades, the industrial automation industry operated under what Gould called the "old paradigm." This is the hierarchical pyramid we ‘re all familiar with — with sensors at the bottom, control and supervision in the middle, and enterprise systems positioned at the top.

While conceptually clean, this model created significant real-world challenges.

"In the old paradigm, software was closed and proprietary, which made organizations get locked into rigid vendor ecosystems that resisted being integrated together," Gould said. "Each application tended to specialize in just one layer, deepening the data silos and making real integration throughout the enterprise nearly impossible."

These limitations weren't just technical; they were also financial. Traditional industrial software imposed what Clegg described as "all sorts of unnecessary limitations” such as “charging for every tag or data point, every client, every designer, every project."

Instead of empowering integrators, this approach "created frustrations and stifled innovation," he added.

The combination of Ignition as the integration platform and IIoT driven by MQTT as the aggregation platform achieved what the Industry 4.0 paper envisioned: Vertical integration of manufacturing systems end-to-end, integration of engineering throughout the entire value chain and horizontal integration of data across the entire enterprise.

These constraints became increasingly problematic as industrial enterprises grew more complex and demanded greater connectivity. The old point-to-point integration model, which relied on connecting one layer up to one layer down, created what Clegg characterizes as "fragile, delicate systems” with “data silos that are hard to penetrate."

Emergence of a new automation paradigm

The breaking point came as industrial companies looked to shift their focus from optimizing individual layers to functioning outside of them entirely. "Modern industrial enterprises want to connect data together. They want to integrate their entire plants, all of their sites, together into a unified system," Clegg explained. Useful data can “come from anywhere, and this has really pushed the old paradigm past the breaking point."

The new paradigm, as described by Clegg and Gould, is built on three core principles that directly address the limitations of traditional systems.

First is what Gould calls an "unlimited mindset." As he put it, "You've got to liberate data from the devices and organize it, contextualize it, store it and share it. You can't be expected to be able to anticipate or predict how many data points you might ever want to collect." He added that this philosophy led to Ignition's unlimited licensing model.

Second is a platform-based approach that spans traditional automation layers rather than operating within them. "If you're going to work outside the layers, you need a common foundation that natively spans them," Clegg emphasized, "not a hodgepodge collection of portfolio companies acquired through the years, but rather a coherent platform that can act as the backbone of your OT operations."

Third is a commitment to openness, interoperability and extensibility. As Gould explained, "True flexibility and innovation comes from systems that prioritize openness, interoperability and extensibility. There are too many disparate systems and too many different industries to pretend that any one system is going to be able to do it all."

Making the Industry 4.0 vision a reality

Clegg and Gould pointed out how much Inductive Automation's approach aligns closely with the vision articulated in the Industry 4.0 paper published 12 years ago. That document proposed two key components for next-generation automation systems: an integration platform spanning traditional automation functions and an aggregation platform providing overarching coordination across layers and sites.

You can't be expected to be able to anticipate or predict how many data points you might ever want to collect.

The emergence of IIoT (Industrial Internet of Things) and the re-emergence in industry of MQTT (message queueing telemetry transport) around 2015 provided crucial pieces to the industrial framework envisioned in the Industry 4.0 paper.

As Gould observed, "What is IIoT besides an end run around the crumbling automation pyramid? What is UNS (unified name space) besides a way to break the data silos and the gatekeeping of old paradigm applications that are locked in those pyramid layers by connecting edge data collection directly to common data infrastructure that's accessible by any application on any layer?"

This combination of Ignition as the integration platform and IIoT driven by MQTT as the aggregation platform achieved what the Industry 4.0 paper envisioned, Gould said. And that is: Vertical integration of manufacturing systems end-to-end, integration of engineering throughout the entire value chain and horizontal integration of data across the entire enterprise.

A key change with Ignition 8.3

The release of Ignition 8.3 represents Inductive Automation's response to the evolving landscape of industrial technologies, where rapid technological advancement is creating opportunities and challenges.

"Ignition 8.3 really is designed to meet the needs of this moment," Gould said. "Not only does it allow you to scale effectively with its infrastructure support, it also ensures that you're building on a foundation that insulates you from the risks and turmoil of constantly changing technology."

One of the most significant innovations in version 8.3 is the introduction of Solution Suites. These curated sets of Ignition modules are built around some of Ignition’s most popular use cases.

Useful data can come from anywhere, and this has really pushed the old paradigm past the breaking point.

As Travis Cox, chief technology evangelist at Inductive Automation, explained, "At first glance, Solution Suites might appear to just be a bundle of modules, which is true. However, when you purchase upgrade protection with Solution Suites, you're entitled to all upgrades to that suite in the future for free. That means that you can take advantage of new modules without having to worry about purchasing more."

The initial five Solution Suites are:

- The Application Building Suite ($13,500) focuses on building applications with real-time dashboards and flexible reporting capabilities.

- The Industrial Historian Suite ($3,500) optimizes time-series data with a built-in historian and trending tools.

- The DataOps Suite ($5,300) streamlines industrial data workflows with event-driven logic and SQL integration.

- The Alarm Management Suite ($3,200) provides smart notifications and flexible escalation paths for alarm management.

- The Enterprise Integration Suite ($4,100) connects plant floor systems to enterprise tools using MQTT and native connectors.

Kevin McClusky, chief technology architect at Inductive Automation, noted that users “can purchase Solution Suites by themselves, purchase individual modules by themselves or any combination of the two."

More technical details about Ignition 8.3 can be seen here.

Building an open ecosystem

Beyond the platform itself, Inductive Automation has fostered what it calls an "open ecosystem based on interoperability" rather than a tightly controlled partner network. Extending this approach is the Ignition Technology Ecosystem, launched in July 2025, which includes more than 40 technology providers offering software applications ranging from connectors and cloud tools to analytics platforms and cybersecurity technologies.

"What makes integration possible with these technologies isn't years of collaboration or custom code. It's the Ignition platform itself," McClusky explained. "These providers can plug into Ignition because the platform's open nature and extensibility were designed to make it easy to do just that."

The ecosystem also includes production-ready software from Inductive Automation’s Gold and Premier integrators, including AI-enhanced development tools and industry-specific applications. Examples include Corso Systems' conversion utility that reduces legacy SCADA migration time by 60%, BW Design Group's AI Perspective Builder for natural language project development, and Flexport Innovation's Spark MES framework for manufacturing visibility and control.

More Automation World insights on Inductive Automation:

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: