Digital technologies are fast becoming core aspects of modern manufacturing as industry increasingly adopts Industry 4.0 concepts for more efficient production processes. But what about the industrial control systems panels that the manufacturing industry relies on to power and control the automated equipment central to their operations?

To find out how the push toward Industry 4.0 is impacting panel builders, we connected with Sanu Warrier (SW), product director for software at nVent, for a recent episode of the Automation World Gets Your Questions Answered podcast. nVent is a supplier of electrical connection and protection solutions including design software and automation machines, electrical enclosures and climate control products that ensure protection for critical components and operations.

Below are a few highlights from our discussion. Hear the complete interview at automationworld.com/55302220.

AW: For panel builders who might be skeptical about the ROI related to Industry 4.0's digitization and automation approach, what's your take on separating the hype from the practical benefits?

SW: When people think about what Industry 4.0 means, they tend to imagine a futuristic, fully autonomous operation that’s all about machines and the Internet of Things. For panel builders, this sounds like it’s eliminating manual work, but in reality, it’s about making incremental gains — it’s not about getting 100% automated on the first day. The practical benefits of Industry 4.0 reach from data-driven design to manufacturing to inventory management support. Given that Industry 4.0 is about incremental gains across manufacturing functions, the practical thing to do is start with a pilot project and assess how it benefits your operation. Industry 4.0 is about how many bites you can take at a time and move forward with the process.

AW: You mentioned design to manufacturing, can you explain how that differs from traditional CAD?

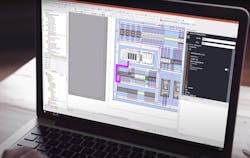

SW: The main purpose of design to manufacturing (DTM) software is to bridge the gap between design and manufacturing to increase overall productivity. Traditional CAD was created to get rid of pen and paper and make it easier to put things together. DTM software is about optimizing the entire design-to-manufacturing process that can drive the creation of digital twins and connect the design process to Industry 4.0.

DTM also helps address long-standing issues such as the friction between engineering and manufacturing by coordinating the work between these two groups with minimal back and forth effort to get more product out the door in less time. This friction between engineering and manufacturing often leads to miscommunication or too much communication, which is not efficient and can lead to errors when people communicate from different perspectives. That’s where DTM comes in to provide a simple solution that enables both groups to store and access the specific data they need.

We’ve seen manufacturers and panel builders save over 20 hours a month just storing all their parts information in DTM software. DTM’s data accessibility and collaboration capabilities help improve accuracy and productivity without increasing headcount, while capturing a company’s inherent knowledge across manufacturing and engineering.

Because the DTM software’s database holds the manufacturing data, it provides the manufacturing perspective to the design engineer right from the start. This enables the design engineer to think about manufacturing even if they not necessarily thinking about it directly — the software is thinking about it when they're doing the design. That’s how DTM makes the whole Industry 4.0 transformation process much easier to start.

For example, the parts library in the software holds all the schematics and panel layout data. That enables the designer to work more efficiently because the software ensures all these data points are up to date. If someone makes a change in one place, it's updated everywhere. This dramatically reduces the errors that can occur in design — and this unified data source drives through to manufacturing.

With the design developed with manufacturing in mind from the start, when it gets to the point where the panel builders are doing the wiring on the shop floor, the DTM software has ensured the holes are routed and aligned correctly and even tells them what lengths of wire they’ll need.

AW: If you had to convince a skeptical panel builder why DTM isn't just another software expense but more of a competitive necessity, what would you tell them?

SW: I would say there are three reasons to consider. Number one, labor costs are not going down and price pressures are rising. This means panel builders need to be thinking about their margins and how they can produce more. These increasing labor and parts costs are causing the margins panel builders once enjoyed to shrink. In addition, there’s the issue of operational margins compared to competitors who are using DTM software. Those costs drop when using DTM software and the machines that go around it for panel building. So, you might be able to continue doing many of the things you need to do without DTM software, but you won't be able to keep up with the market pace.

The second reason is the expert workers that panel builders have relied on for the last few decades are retiring and it can be difficult to train and retain new employees today. If you want to keep new people around, you need more modern processes. The new generation of workers grew up with iPhones and the internet, so they want more than just a pen and paper to keep their jobs interesting.

The third reason is that many owners of panel building companies want to pass their business on to a successor or sell it. Hanging on to your old approach to panel building can make it tougher for someone else to take over the business because they won’t necessarily know how you do everything. DTM software enables the capture and transfer of critical panel building knowledge by solidifying it inside the software, inside processes and inside the machines. Even if you’re not looking to sell your business, as I mentioned earlier, if a key person is retiring, you're not losing that knowledge they’ve built over the years.

AW: For panel builders who are onboard with the idea of adopting DTM software for its benefits but are worried about moving away from their current panel building processes, what’s your advice to them about getting started with DTM without disrupting their current operations?

SW: That’s actually a conversation we have all the time. We tell those panel builders that if you don't want to disrupt what you’re doing, then you're in the right track because change is never easy. This gets back to what I was saying earlier about Industry 4.0 and starting with a pilot project. You don't need to do everything on day one.

With this pilot project, make sure you’re not disrupting your current operations. Pick one or two people that can start with it and go all in on it mentally but start small. Do one or two projects and learn from them what needs to change about a specific process. These champions can then bring in other people to the software and its processes, but it’s important to invest in training and implementation at this stage because different people will take to change differently. Be sure to remain focused on making small changes to help with acceptance.

And give yourself a timeline to phase it in. Don't pick the biggest project you've ever done to start with this new software. Pick some process you know well to start with so that you can get quick insights with DTM compared to how you have traditionally performed the process.

nVent also helps provide the training and support that’s important at this early stage, because a customer’s success is our success. If the customer is not successful in the long run, we're not going to be successful. So, it's not about throwing boxes of software at them, it's about providing a solution and then growing with that customer.