Stanley Black & Decker Backs Injection Molding/3D Printing Combination

Developed for the purpose of replacing short run or manual processes that currently exist in industrial injection molding, the Inj3ctor from Structur3d is reportedly the first additive manufacturing system to combine the principles of injection molding with 3D printing.

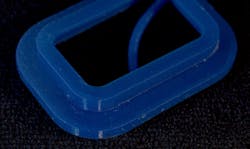

According to Structur3d, the Inj3ctor uses curated material cartridges to mix and inject 2-component flexible materials into any customizable shape, enabling turnkey, small-batch manufacturing of rubber materials.

Zhong added that he sees Structur3d advancing prototyping by “opening up the arsenal we have available to tackle rubber components that are both easy to use, turnkey, and can produce a real, usable geometry prototype with the actual material you tend to use in production.”

Finkel said product developers can “design a hyper-detailed mold using standard CAD software and 3D print the part with standard, durable or dissolvable plastic. Then users can choose from tens of thousands of liquid rubber materials, customizing it based on desired durability, flexibility, and cure time. After programming the mixing ratio and injection volume, the Inj3ctor fills in the mold, creating a fully customized, flexible product.”