Flexible and Modular CIP and SIP Automation Enables Continuous Improvements

Clean-in-Place (CIP) and Steam-in-Place (SIP) constitute critical aspects of the bottom line of a manufacturing process—just as important as the products manufactured with the assets. CIP and SIP play a very important role in the product quality, as well as the overall availability of the equipment to manufacture these products. Being able to consistently execute the required cleaning step regardless of the equipment level of automation is paramount—and being able to clearly specify and enforce the steps required are critical regardless of how these tasks are executed. Operators and equipment should seamlessly perform their task to ensure the desired cleaning procedures are executed in an optimum manner.

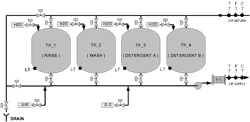

Often CIP and SIP sequences are programmed in a controller and provide little opportunity to further optimize the process other than changing a set of pre-defined parameters—preliminary flush with water, caustic/acid cleaning, final rinse, etc. The capabilities of what can be done with the equipment and personnel are often truncated by preprogrammed sequences that do the job, but often are not optimized because of the complexities associated with modifying the controller code to adapt to multiple scenarios.

To optimize the CIP and SIP processes, the system should allow a procedure author to design, implement, test, and deploy procedures without requiring engineering resources. This enables procedures to continuously be improved and optimized or to adapt to changing requirements.

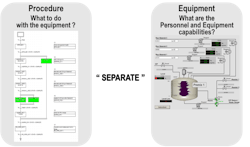

ISA-88 and ISA-95 concepts help us develop systems that are modular and flexible by exposing to the recipe author what the capabilities of the equipment and personnel are and allowing the author to graphically specify how these capabilities should be used. For example, perform initial water rinse to drain until a condition is met or transfer this initial rinse solution to a downstream destination before sending to drain, therefore performing a system initial wash versus a tank initial wash.

This flexibility is especially valuable not only for new process equipment during the development of the cleaning procedures but also for processes that are constantly innovating by creating new product or by new materials that force different cleaning requirements.

The ISA-88 and ISA-95 approach not only allow you to combine in a procedural model the automated and manual operator activities required to perform a consistent CIP/SIP, but also allow you to verify that the required activities were performed—which is achieved by the automatic journaling of all pertinent activities. Off-the-shelf products provide the infrastructure to deploy these types of solutions.

This approach provides engineers a well-defined scope of work focused on exposing the equipment capabilities to the recipe author, leaving the recipe author the ability to configure reusable procedures based on the equipment capabilities without requiring engineering changes. It allows the end-user to clearly specify what automated and manual steps are required, enforce their execution, and provide ample information to corroborate that all steps have been followed.

Randy Otto is CEO of ECS Solutions, a certified member of the Control System Integrators Association (CSIA). For more information about ECS Solutions, visit its profile on the CSIA Industrial Automation Exchange.About the Author

Randy Otto

CEO of ECS Solutions

Randy Otto is the CEO of ECS Solutions and brings more than 25 years of experience in diverse industries, including glass fibers manufacturing and custom assembly machine manufacturing. Before joining ECS, Randy spent 10 years managing the delivery of assembly equipment for Integrated Systems Manufacturing and process control systems for Premier System Integrators. For most of the last 12 years, he has managed business development and sales for ECS. Randy graduated from Purdue University with a degree in electrical engineering technology. He has an MBA from the University of Southern Indiana.

Leaders relevant to this article: