Toshiba Machine (TM), a producer of industrial robots for more than two decades, has announced the launch of two new collaborative robots (cobots), expanding on the company’s line of industrial robots.

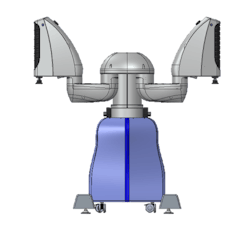

The newly announced cobots— a humanoid duo-arm cobot and a SCARA duo-arm cobot—are the first cobots from TM. Both will be available in 2021.

TM’s humanoid cobot features a 6kg maximum payload for each arm or 10kg when used in combination. It was developed for human-machine collaboration in parts assembly and inspection processes.

The collaborative SCARA robot expands on TM’s experience manufacturing traditional SCARA robots. The collaborative SCARA robot features two arms and is suited to fast-paced handling applications. According to TM, the SCARA demonstrates how a cobot can be used in delicate electronics handling and packaging applications—a task usually limited to highly accurate industrial machines.

Also of note, starting April 1, 2020, TM will return to its original name of Shibaura Machine. The name change represents a formal separation from Toshiba Corporation, but will not impact the new product releases mentioned here.

“The corporate name change will have no bearing on TM Robotics and our global distributor network, nor will it change the outstanding quality of the industrial robots—and now collaborative machines—that we offer at TM Robotics,” said Nigel Smith, managing director of TM Robotics.