Comau started offering industrial automation solutions for the automotive sector more than 50 years ago for many of the world’s biggest car manufacturers. As automation technology has changed over the years, so has its reach. Today, in fact, Comau is applying its field-proven experience and process expertise to meet the rising demand for automation in diversified industries such as warehousing and logistics, food and beverages, pharmaceuticals, renewable energy and other sectors looking to increase quality and efficiency with tailored automation solutions. The global technology company has now returned to Automate to showcase its portfolio of sustainable, advanced automation solutions that drive the Power of Automation across diversified industries.

To address the dynamic changes happening within fast-growing markets, Comau has developed a groundbreaking portfolio of AI-backed automation solutions that can be tailored to the task at hand. As more and more industries look to automate intricate and highly variable processes, they are often challenged by the growing shortage of expert workers and a widening automation skills gap. Another important issue concerns the need for increased process variability and inherent scalability without compromising ease-of-use, which is especially important for companies that are new to automation. For these reasons, Comau’s advanced solutions are also increasingly accessible and intuitive.

Comau advanced intelligence developments respond to the continued worldwide growth of the industrial automation sector, which the company expects to reach growth rates of up to 14% CAGR 2024-2030 according to internal estimates and supporting market research. Automate is therefore an ideal backdrop to unveil its transformative approach towards intelligent, software-driven solutions that go beyond the factory and beyond the equipment itself.

With more than 50 years of experience in automotive, one of the most complex realities in terms of processes, cycle times, flexibility requirements and technology rates, Comau is in a prime position to meet the growing demand for sustainable automation, particularly in emerging sectors that have previously lacked automation.

Whereas the automotive sector has traditionally relied on specially trained experts to program and operate their highly automated assembly lines, the complex and non-linear manufacturing tasks Comau is now automating have traditionally relied heavily on skilled human labor to navigate their dynamic nature. Today, however, the strong demand within non-automotive sectors is driving the need for open automation that is easy to implement, easy to use and increasingly able to autonomously respond to changes in the surrounding environment. As a 360° automation partner able to quickly transition from R&D to field-tested deployable innovation, the company is constantly forging new ground to harness the power of automation and drive increasingly complex manufacturing tasks all over the world.

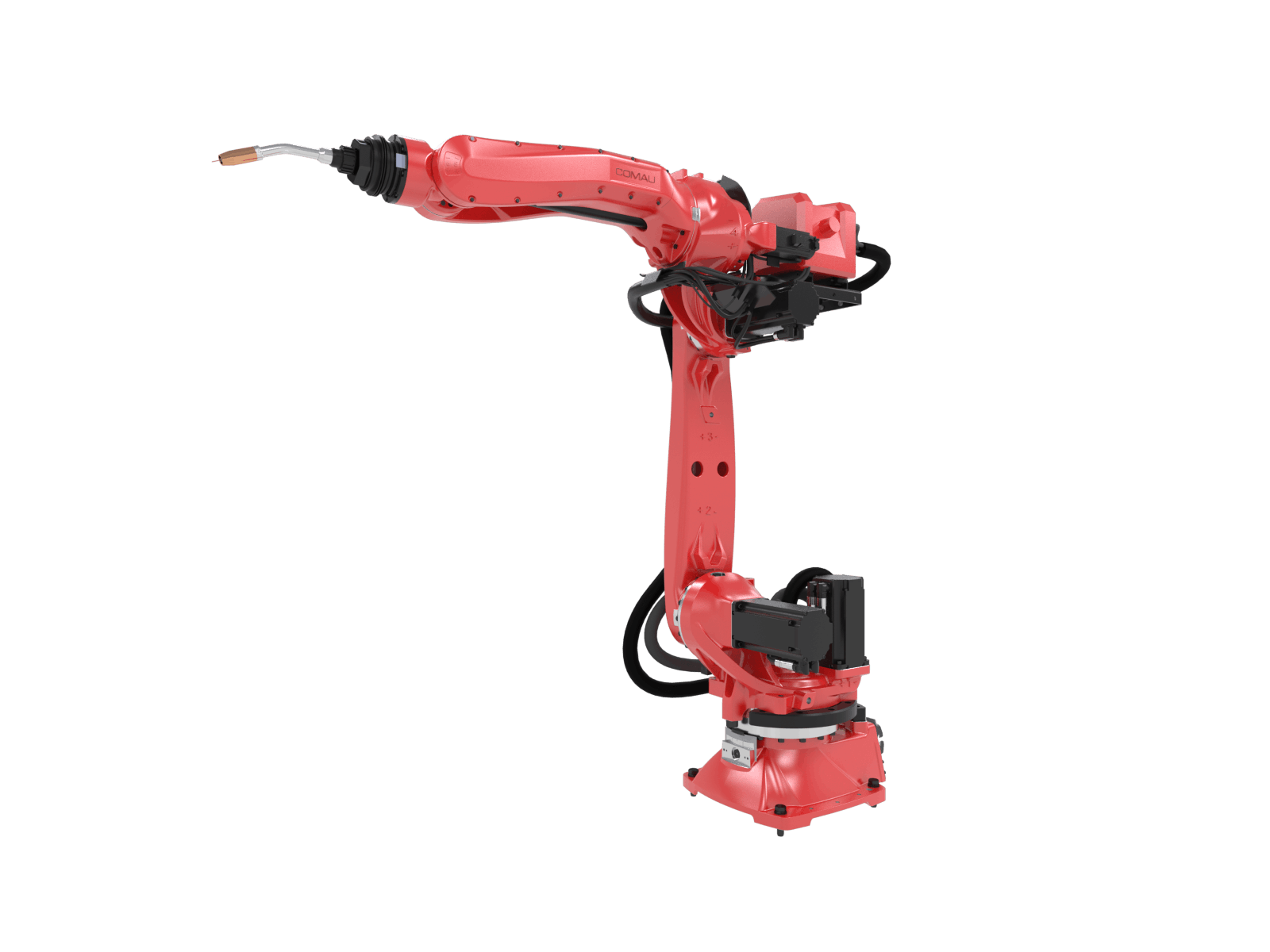

Underscoring its global presence and local roots, Comau is launching its newest dedicated S-Family of robots at Automate. The compact, robust and versatile robots, with which Comau returns to its historical red robot roots, feature payloads of 13 kg and 18 kg respectively and are specifically designed for high speed applications where accuracy and repeatability are non-negotiable. With their protective water and dust-resistant IP68 hollow-wrist design, both of the 6-axis articulated robots are perfect for a wide range of arc welding, handling, food & beverage and general assembly applications, in addition to foundry, automotive, and battery manufacturing processes. Further benefits include improved access to small spaces, protected cables to avoid damage and reduce the risk of contamination in sensitive environments, integrated arc and gigabit dressings and multiple mounting positions to save space without sacrificing performance.

Another way that Comau is reducing barriers to automation is by making the deployment and management of advanced robotic solutions increasingly more intuitive. This includes the intelligent programming paradigms found within its robot control software. The new Comau Open Controller, for example, enables external PCs to seamlessly control Comau robots. This means that companies, universities and research centers can now implement proprietary motion strategies and algorithms to control the robot rather than relying on pre-configured path management sequences. Similarly, Comau’s Roboshop Next Gen is an intuitive, PC-based programming tool that allows customers to program a robot and graphically optimize its path before online deployment.

Sustainability, both in terms of energy and consumption efficiency as well as general well-being, is another performance indicator that is becoming increasingly important as the pace of change accelerates. Aligned with its steadfast commitment to helping companies achieve their sustainability goals, Comau’s technology design and deployment strategy includes concrete energy and ESG objectives.

To promote increased worker well-being, on the other hand, Comau has developed its MATE-XT (upper body) and MATE-XB (lower body) wearable exoskeletons. Both are designed to assist the wearer during lifting, bending and repetitive tasks by offering both muscular relief and reduced perceived effort. In this way, the exoskeletons protect both worker well-being and the quality of manual tasks. As importantly, they can also help individuals who, without the proper assistance, may be excluded from certain types of work.

Similarly, Comau’s upskilling and reskilling initiatives, which are based on its innovative educational e.DO™ robot, are yet another way Comau is promoting worker-focused sustainability. From digital skills training, robot programming, simulated welding training, and more, the unique e.DO™ platform is helping companies and individuals address skills gaps.

For a brief video demonstration of the new products, click here.