Low-Cost Robotics for Industrial Inspection

Inspection robots are transforming how industries conduct inspections and maintain quality control, ensuring greater accuracy, efficiency and consistency. Yet while the benefits of inspection robots are clear, the path to automating these processes is not always so.

Some of the challenges include the inherent complexity and cost associated with implementing automated inspection systems, requiring the integration of robots, high-resolution cameras, sensors and software into existing manufacturing processes. The financial investment for these technologies can also be significant, posing a barrier for small and medium-sized companies.

New, low-cost robotics, however, are enabling manufacturers of all sizes to easily automate their quality control and inspection operations. These systems break down automation solutions into individual components and then find the lowest-cost parts that meet the required specifications. By aggregating the key components in this way, this robotics platform enables manufacturers to design, build and purchase an inspection robot that meets their unique application needs.

To show how this approach works, igus has developed a robotic platform that provides a cost-effective, flexible and user-friendly automation on-ramp for inspection tasks.

The igus RBTX platform

Online platforms, like igus’s RBTX, make robotic systems more accessible by addressing two cost issues that often keep manufacturers from adopting automation: hardware and implementation.

Addressing the hardware aspect, RBTX breaks down and aggregates individual, low-cost components from leading manufacturers. This eases the process of sourcing the many elements required in an automated inspection system.

To mitigate the issues commonly associated with complex automated system implementations, RBTX consolidates all necessary information into a single place, saving users time otherwise spent on research. The platform also offers consultation and testing services, guaranteeing the feasibility of the inspection system before it is delivered. Services like remote integration support, video consultations and application tests are also available to help ensure the system’s effectiveness prior to delivery.

A scalable roadmap for automated inspection

Once a robotic system has been tested and implemented, it’s easy for users to install more of the same system without having to repeat the entire integration process. This strategy allows manufacturers to start small and expand their production while reducing upfront costs.

For example, the six-axis ReBeL robotic arm arm from igus starts at just under $4,500. This robot arm is compatible with various end effectors, camera systems and accessories and can be used as a collaborative robot (cobot). It is up to two times lighter than other cobots and integrates the control system in its base, eliminating the need for a separate control cabinet.

Higher up the ladder in terms of cost and complexity is an entire robotic work cell. For example, a six-axis robotic arm and cell would cost just over $24,000. In one application, this system successfully replaced a human worker, who was reassigned to more complex and value-added tasks. The cobot took over the repetitive and monotonous functional inspection of water faucets with high precision and reliability.

Inspection application examples

Following are seven common application examples for which RBTX can be used for an automated inspection system:

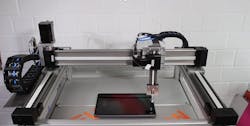

Touchscreen quality assurance. With the proliferation of smart phones and other electronic devices, ensuring the quality of touchscreens has become more critical than ever. The RBTX platform offers linear robots and XYZ gantry systems controlled via igus’s Robot Control software for such applications. These robotic systems can accommodate the varying sizes and interfaces of different touchscreens, with the platform offering a high pick rate of 30 per minute with an accuracy of 0.1 mm.

Surface inspection. One of igus’s manufacturing customers that specializes in control technology uses a scanner, igus line gantry and Apiro gear to inspect workpiece surfaces for irregularities. The scanner moves with the gantry over each workpiece, performing rotary movements to detect surface defects with 0.5 mm accuracy. This robotic system is also compatible with various end effectors, camera systems and other accessories for use in various inspection tasks across industries.

Quality control of remote controls. RBTX has also been used for the quality control of TV remote controls. This application includes an igus area portal and end effector to test each remote control within a specified time frame, ensuring compliance with production cycle times.

Precision testing. RBTX supports the use of gantry robots for precision testing. These robots are equipped with linear axes that enable multidimensional movements, making them suitable for diverse quality control tasks. For example, a gantry robot equipped with a two-finger vacuum gripper can position smartphones correctly and test their functions and touchscreens.

Quality assurance. The ReBeL cobot, available through the RBTX platform, is particularly effective in quality control applications, including the handling of delicate items. It also features a compact design, 360-degree rotatable joints and the ability to lift payloads up to 2 kilograms.

Visual inspection. The RBTX platform facilitates camera-supported quality assurance systems. These systems use cameras in conjunction with robotic arms to perform detailed inspections of products. For example, the integration of visual servoing technology allows robots to achieve precision levels of 0.01 to 0.02 mm, which is crucial for the quality control of small and intricate components like those found in electronics manufacturing.

Automated printed circuit board (PCB) inspection. This application involves the use of robots to test the quality of PCBs, ensuring they meet the required standards before being integrated into electronic devices. The platform's ability to integrate AI and robotics enhances the precision and reliability of these inspections.

By Jan Hennecke is product manager, low-cost automation, igus.