A Clearer Vision for Manufacturing Quality Control

Why this article is worth reading:

- Learn how cloud-centralized, AI-powered vision systems are transforming traditional quality control by eliminating the need for costly, rigid and expertise-heavy setups.

- Find out how manufacturers can benefit from the reduced total cost of ownership, faster deployment, and easier scalability associated with AI-powered vision systems.

- Get insights into how AI-driven systems adapt to changing production conditions and integrate with broader analytics platforms, enabling quality insights that were previously unattainable.

Throughout the past 80 years of industrial machine vision system development and use, these systems have typically involved the use of an industrial computer that coordinates peripheral devices — such as cameras and lighting — to analyze information via software. These vision systems have driven significant improvements in quality control, resulting in improved throughput, fewer quality issues and improved course-correction activities.

However, recent advances in artificial intelligence (AI) and cloud technologies have highlighted inherent limitations that challenge the effectiveness of these industrial vision systems. In addition, these traditional vision systems carry significant financial and operational burdens that many manufacturers are no longer willing to tolerate.

This is driving the emergence of a new economic model that leverages cloud-centralized, AI-driven vision to deliver adaptive learning, scalable connectivity and quality control functionality to manufacturers regardless of location or size.

Industrial vision system limitations

Traditional industrial vision systems demand significant upfront investments in hardware, software and specialized programming expertise. Each application requires custom configuration that can take weeks of development by expensive vision specialists.

Even once deployed, the cost of these systems continues to accrue with new product variants or quality parameters that can require complete reprogramming of the vision system. Plus, extensive calibration procedures require technical expertise and significant time investment, creating downtime when production specifications change.

One of the most significant advantages of cloud-centralized systems is their ability to aggregate visual data across multiple production lines or facilities. This creates new opportunities for cross-line learning and system improvement. For example, a defect detected in one factory can immediately update inspection parameters in all connected facilities, creating a continuously improving inspection network.

These systems also tend to operate as islands of automation, generating quality data that rarely connects to broader manufacturing intelligence systems, preventing enterprise-wide insights that could drive incremental improvement.

Performance of these systems can be affected by environmental sensitivity, such as variable lighting, dust, vibration and temperature fluctuations, requiring additional protective measures that increase complexity and cost.

Many traditional vision systems also struggle with real-time analysis of high-resolution images in high-speed production environments, especially when using complex image recognition algorithms. And there’s also the inherent trade-off between field-of-view and resolution, forcing compromises between detecting small defects and inspecting larger areas.

Other issues with traditional machine vision technology include:

- Conventional 2D imaging technology lacks depth perception, creating challenges for inspecting complex 3D geometries and component positioning.

- Interpretation challenges mean that inherent systems struggle to translate pixel data into accurate inspection decisions, resulting in false positives, false negatives and inconsistent defect recognition.

Cloud-centralized AI vision: A new economic model

The emergence of cloud-centralized, AI vision systems represent not just a technological evolution but a fundamental shift in the economic model of industrial inspection, reshaping how manufacturers evaluate, implement and calculate ROI for vision systems across their operations.

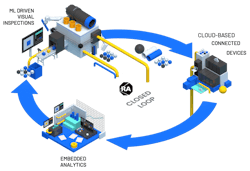

In terms of architecture, cloud-centralized AI vision systems typically operate through a multi-layered architecture:

- Edge devices (cameras and basic processing units) capture high-resolution images on the production line.

- Local gateways manage data transfer and preliminary filtering.

- Cloud infrastructure provides massive computational resources for AI model execution.

- Centralized databases store historical image data and inspection results.

- Feedback mechanisms continuously refine detection algorithms based on performance.

This distributed architecture separates data acquisition from processing and decision-making, thus creating substantial economic and operational advantages previously unattainable with traditional systems.

Scaling and data aggregation benefits

One of the most significant advantages of cloud-centralized systems is their ability to aggregate visual data across multiple production lines or facilities. This creates new opportunities for cross-line learning and system improvement. For example, a defect detected in one factory can immediately update inspection parameters in all connected facilities, creating a continuously improving inspection network.

The scalability of cloud resources also addresses the processing speed limitations of traditional systems. When confronted with computationally intensive inspection tasks, cloud-based systems can dynamically allocate additional resources rather than being constrained by local hardware limitations.

In the conventional vision system model, each manufacturing facility required dedicated vision specialists and system administrators. Cloud-centralized approaches enable a single team to manage vision systems across multiple global facilities from one location. This consolidation dramatically reduces staffing requirements while increasing consistency.

System-wide updates that previously required on-site visits can now be deployed remotely through cloud infrastructure. When quality specifications change or new detection requirements emerge, updates can be pushed across all connected systems simultaneously, eliminating travel costs and drastically reducing implementation time.

Traditional vision systems required extensive parameter configuration and rules-based programming by specialists with deep technical expertise. AI-based systems learn from examples, allowing quality personnel without programming backgrounds to train the technology by providing good and bad samples to the system.

The most significant economic impact comes from the fundamentally different approach to system configuration. Traditional vision systems required extensive parameter configuration and rules-based programming by specialists with deep technical expertise. AI-based systems learn from examples, allowing quality personnel without programming backgrounds to train the technology by providing good and bad samples to the system. This approach dramatically expands who can configure and maintain vision systems. The reduction in specialized expertise also translates to faster deployment.

Adaptive learning and reduced maintenance

Conventional vision systems require frequent recalibration as production variables naturally shift over time. AI-based systems fundamentally change this maintenance equation through adaptive capabilities.

Manufacturing environments experience subtle changes in lighting, material properties and mechanical wear. While traditional systems gradually drift out of calibration as these changes accumulate, some AI vision systems continuously learn from production data, automatically adjusting without human intervention. This adaptability can reduce maintenance requirements across multiple implementations and improve precision in distinguishing actual defects from acceptable variations.

When vision data flows into broader manufacturing analytics systems, its value extends far beyond simple pass/fail decisions. Cloud-centralized systems can correlate visual inspection data across multiple production lines, identifying patterns invisible to traditional isolated systems. Visual inspection data can also reveal subtle changes in product appearance that precede equipment failure.

Total cost of ownership (TCO) advantages

When calculating total cost of ownership, manufacturers must consider implementation time, ongoing maintenance, integration capabilities and scalability. Cloud-centralized systems can offer significant savings by reducing the burden of maintaining on-premises infrastructure, eliminating the need to purchase, support and regularly upgrade compute and storage hardware.

Perhaps the most significant TCO factor is the system’s ability to adapt to evolving requirements and production changes. For example, as stock-keeping unit (SKU) proliferation increases to meet shifting customer demands, traditional systems often require a machine vision engineer to visit the plant and manually update inspection recipes. With a cloud-based AI system, plant personnel can update inspection models directly through a web browser, minimizing downtime and reducing reliance on specialized support.

Jonathan Stanwood is technical enablement consultant at Rockwell Automation.

More machine vision insights from Automation World:

About the Author

Leaders relevant to this article: