Norfolk Southern Shows How AI-Powered Vision Systems Are Revolutionizing Industrial Inspection

- Norfolk Southern's AI-powered Digital Train Inspection portals detected more than 25,000 mechanical defects in 2024, including 87 severe issues requiring immediate action and the industry's first-ever detection of a cracked wheel.

- The system captures 1,000 images per train car using 38 ultra high-resolution cameras while trains pass through at 60 mph, demonstrating AI vision's ability to perform detailed inspections at operational speeds that would be impossible with traditional methods.

- The technology combines advanced hardware with AI algorithms, automated notifications, and human oversight protocols to create a near real-time inspection process that prevents costly failures and safety incidents before they occur.

We all hear a lot about AI, likely too much. But one of the applications of AI in industry that consistently proves its worth is its use in machine vision systems to detect defects or anomalies. If you haven’t yet been inundated with details on such AI applications, several articles and podcasts on AI-powered machine vision applications in manufacturing from Automation World can be accessed at the bottom of this article.

To highlight just how important AI-powered vision is quickly becoming for industry, I want to highlight an application I heard about while attending the RoboGeorgia Summit 2025 at the Georgia Tech Research Institute. This project between Norfolk Southern and Georgia Tech involved the use of AI-powered vision systems to inspect cargo train cars. The session featured representatives directly involved with the project: Mabby Amouie, assistant vice president of enterprise data and analytics at Norfolk Southern; Gary McMurray, associate director of the Institute for Robotics and Intelligent Machines at Georgia Tech; and Colin Usher, research scientist at the Georgia Tech Research Institute.

Though the inspection of cargo train cars may seem worlds apart from the manufacturing industries’ use of AI-powered vision, the Norfolk Southern/Georgia Tech project did a great job of highlighting the capabilities of the technology for all industries.

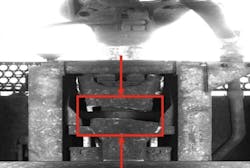

Here's why I say this: For starters, the cargo train cars being inspected are not idle during the inspection — they are passing through a constructed inspection unit (called a Digital Train Inspection portal) at 60 mph. These portals contain:

- 38 ultra high-resolution (24 megapixel) cameras with stadium lighting to provide a 360? view of a cargo train car.

- AI-powered software designed to capture sub-millisecond synced imaging (1,000 images per car).

According to Amouie, in 2024 the inspection portals found more than 25,000 mechanical defects that required addressing by Norfolk Southern’s mechanical team. He noted that 87 of those captured defects had “higher levels of severity” that required an immediate train stop and repair or speed reduction for the train to reach the next stop safely.

Most notably, Amouie said the cameras captured “the first ever cracked wheel detected in the industry.” While this may not sound like a big deal to those outside the rail industry, Amouie said the visual appearance of these cracks typically occur just before a wheel shatters. Therefore, cracked wheels are not something that would ever be seen in the cracked state before the wheel’s failure.

Beyond the hardware and software aspects of the inspection portals, Amouie explained the “end-to-end process” associated with the inspection process. He said the AI algorithms in the software developed for the portals can issue automated notifications in near real-time. Norfolk Southern also has a team of people viewing the images highlighted by the system who are trained in specific response protocols to advise on the need for train stops, slowdowns and maintenance calls.

For manufacturers, the Norfolk Southern/Georgia Tech AI-powered vision project demonstrates the potential of this technology to solve critical operational challenges that have previously been unaddressed or considered unaddressable. The ability to detect microscopic defects at high speeds with unprecedented accuracy — such as wheel cracks that occur moments before catastrophic failure — illustrates how AI vision systems can prevent costly downtime, safety incidents and quality issues that traditional inspection methods simply cannot catch.

Whether inspecting moving train cars at 60 mph or products on a high-speed production line, the core value proposition remains the same: AI-powered vision provides manufacturers with superhuman detection capabilities that can identify problems before they become expensive failures, ultimately protecting both operational efficiency and bottom-line profitability.

Because manufacturing continues to demand higher speeds, tighter quality tolerances and zero-defect production, I shared these insights from Norfolk Southern and Georgia Tech to illustrate how AI-powered vision systems are proving themselves to be an operational necessity.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: