Manufacturer uses OPC to integrate legacy control with A-B ControlLogix robotic controller

Since 1971, Task Force Tips (TFT) in Valparaiso, Indiana has manufactured high quality water delivery solutions to clients worldwide. Their focus is on nozzles for the firefighting industry but their product offerings include hoses, valves, nozzles for de-icing, and foam solutions.

For many years TFT has had a robotic picker picking from hundreds of parts bins along a 100 foot multi-level picking line. The robot was controlled by a COBOL program via serial connection running on a Linux box. This picking line had become problematic with frequent breakdowns and slow response time to commands.

The team at TFT began to explore solutions to make the line more reliable and efficient. To accomplish this, they began by completely overhauling the robot. For control, they chose Allen-Bradley ControlLogix PLCs and A-B servo drives. The question for TFT then became, how to maintain their control program on the Linux box and use it to pass commands to the ControlLogix PLC. It was suggested that TFT investigate OPC technology.

After many hours researching OPC and how it would be useful to their application, Stewart McMillan, President of TFT, contacted Software Toolbox. Stewart found that Software Toolbox could provide a single source for the tools and service to create a solution using the TOP Server OPC Server and OPC DataHub® from Cogent Real-Time Systems, Stewart was able to find a solution that fit the needs and the budget of the project. Using the TOP Server Allen-Bradley driver suite (specifically, ControlLogix Ethernet driver) and the OPC DataHub the existing COBOL program was able to be retained for use with the new and improved control hardware. As Stewart McMillan says, “It is magical what this can do for our application.”

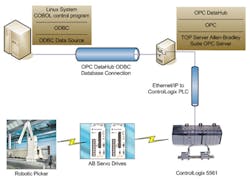

In this application the TOP Server is connected to the ControlLogix PLC and the OPC DataHub. The OPC DataHub through its ODBC interface is connected to an ODBC data source. The COBOL program passes commands as parameters to this data source, which the OPC DataHub reads into OPC data points which then are written through TOP Server to the PLC for control. The responses to these commands are then passed back through this chain to the ODBC data source to be read by the COBOL program to determine the next step in the sequence.

TFT has seen significant improvement in efficiency of the line and to date, has nearly eliminated downtime on the line. According to Stewart McMillan, “It is really a pretty unique application. It is so much faster than what we had before! Now we are trying to find other problems to solve.” In regards to the application he goes on to say: “I think that it is an unusual way to use the technology but has been VERY effective for our business results.”