New technology enables rapid-refresh, high-performance display of OPC data on Web-based HMI's

As the world continues moving towards the Web, and pulls the industrial automation sector with it, we are demanding better quality Web-based HMIs. In the past, taking data from an OPC server and attempting to display it on the Web produced disappointing results. Graphics were low quality, and data rates were slow. You needed a full off-line development environment and coding skills just to build real-time Web displays. Now, recent advances in browser capabilities allow browser-based screen editors to deliver the kind of point and click simplicity that makes anyone a page developer. With this advance come greater expectations—a demand for top performance.

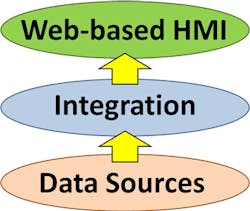

A key advantage of a Web HMI is to realize the promise of OPC, to step outside the box carefully constructed by a DCS or SCADA vendor, and tap into data from other sources. Of course, some users don't have a DCS or SCADA system, and don't really need one. They just need a flexible way to access their data, and potentially interact with the data from within the Web environment. In either case, to access data from multiple sources, or to convert, analyze or synthesize data on the fly, a truly useful Web-based HMI can benefit greatly from a robust middleware foundation.

There have been several approaches to meet this need. Some vendors offer a relational database foundation, where real-time data is collected from PLCs and stored in an SQL database for access by clients, using a polling mechanism. The overhead in processing speed makes it difficult for this kind of system to handle the hundreds or thousands of data changes per second needed by many industrial systems. Other solutions offer real-time connections to specific data protocols, but no way to aggregate them into a single, common data set, which is the goal when providing a plant-wide perspective on the Web.

A more satisfactory solution is to implement a dedicated middleware product to connect to all data sources, integrate them, and then feed the results to the Web-based HMI. When done properly, by using an in-memory event-driven database for example, this approach offers the following advantages:

1) Low latency. Web-based HMI with integrated middleware can update HMI controls like gauges and trends as quickly as the network latency will allow, which is typically faster than the human eye can detect. Additionally, every point change is available to the system for historical archiving, rather than being lost in a polling cycle.

2) Robust capacity. Well-written OPC middleware can support data set sizes of tens of thousands of tags, data throughput of up to a hundred thousand data changes per second, and hundreds of simultaneous Web browser connections. Most systems don't need quite this much power, but having it available means that a smaller scale application will run that much more efficiently.

3) Real-time integration. OPC-enabled middleware can provide OPC tunnelling, server-to-server bridging, data aggregation, and support for redundant data sources. It can also integrate data from databases, Excel spreadsheets, and custom applications and feed it to the Web HMI.

For more information, visit www.cogent.ca.