OPC Tunneller Bridges Wind Turbines and Power Station

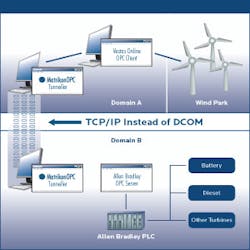

Although the two networks were physically connected, it was not possible to logically link the two systems due to domain and DCOM issues. After some good experiences with MatrikonOPC Explorer, an OPC client utility, during early commissioning of the Vestas network, Hydro Tasmania Consulting chose MatrikonOPC Tunneller to provide the bridge between the two networks. Tunneller provides an easy, reliable and effective way to communicate across different network domains and does away with the headaches typically associated with the configuration of DCOM. The implementation of this software was carried out painlessly, and any technical problems were quickly overcome with technical assistance from Matrikon Australia.

"MatrikonOPC Tunneller was literally Plug and Play," says Simon van der Aa, Control Systems Engineer with Hydro Tasmania Consulting. "Once we installed it and followed the simple configuration instructions, we haven't had to touch it. Since it was installed, MatrikonOPC Tunneller has been pretty much transparent."

Via this OPC connection, the Station Controller can control the wind turbines, allowing them to be integrated seamlessly into the overall station control philosophy. The station is capable of running unmanned, and schedules and loads the generators according to customer loading and wind conditions. The Station Controller can also log many parameters of the station and wind turbine operation, allowing the operators to quickly locate and troubleshoot faults that may occur. Approximately 20 parameters are transferred between the two systems every second.

For more information on OPC solutions from MatrikonOPC, visit www.matrikonopc.com.