OPC Interface for Wind Farm Condition Monitoring System

Softing, a world leader in providing conformant OPC development and OPC middleware tools, provides integral OPC components to support a Condition Monitoring System for wind turbines. Early detection of potential equipment failure in a harsh environment supports the implementation of a cost-optimized preventative maintenance strategy to avoid serious and expensive damage to the wind turbine.

The solution to early problem detection is the permanent acquisition of strategic data. Condition monitoring systems (CMS) collect and analyze raw data from the process (or functional units) and monitor them for changes. This data is transformed into meaningful information that, in turn, ensures sound decisions for preventive maintenance of the system.

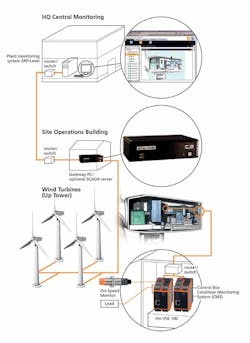

Vibration sensors (efector octavis) and visualization systems (CMSpro) from ifm electronic jointly form an online condition monitoring system that automatically monitors vibration indicators. The raw data is collected via an event-driven mechanism. Up to 24 freely configurable condition indicators are calculated from the enormous data volume of up to 25,000 vibration-values per second. These indicators are then monitored for infractions of a configured limit value. The resulting data is transferred to an industrial-PC (IPC) provided by Softing that is preconfigured with Softing’s leading OPC Easy Connect Suite to allow remote data management via an industry-standard OPC interface.

This system enables the remote monitoring of hundreds of wind farms from a central control station. Unintended failures of turbines are avoided, uptime is maximized, and the cost for operation and maintenance are minimized due to preventive maintenance measures. The different components of the condition monitoring system are preinstalled and preconfigured. Wind farm operators, therefore, receive a flexible and reliable, all-in-one solution from one supplier.

Softing North America, Inc.

978.499.9650

www.softing.us