Cut through Complexity with Role-Specific KPIs

Manufacturers who seek improved performance achieve the highest return from their efforts when they are able to leverage technology to tie information to action. Manufacturing Intelligence, at its best, should empower individuals to tailor their day-to-day activities to improving overall production results. To do so, they must have visibility into a range of data, an understanding of how those measurements affect operations, and clearly-defined action-steps appropriate to their role.

Achieving that insight despite the ever-increasing complexity of plant-floor requires the type of unified production model provided by FactoryTalk Metrics, FactoryTalk Historian and FactoryTalk VantagePoint from Rockwell Automation.

FactoryTalk Metrics is critical to providing accurate information from plant-floor equipment detailing custom or user-defined information for KPI or event data collection related to machine performance including details like:

- Total/good/scrap production counts

- Part ID and cycle time

- Status and shift – time patterns and exceptions

- Run time indicator

FactoryTalk Historian provides accurate and scalable process data capture. On a single machine, Historian ME can gather highly-granular information from up to four controllers on a backplane without the danger of server or network disruption. Historian SE supplies complex process data to a centralized location in the plant, from a single subassembly to a production line and across a plant.

Both Metrics and Historian products are quickly and easily configurable, enabling users to locate sources of inefficiencies in a range of Key Performance areas. Once that key production information is captured, FactoryTalk VantagePoint is uniquely positioned to maximize its usability.

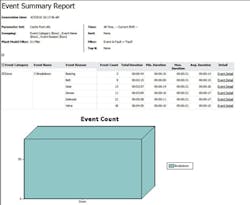

VantagePoint places information from disparate systems into context and provides visibility into production through a web-based reporting tool that gives users a fully-fleshed picture of what factors are contributing to weak spots in performance and how each relates to the other. That information can come from all over the plant: from Metrics and Historian, as well as from sensors and business systems. Perhaps more difficult to manage, that information can come from systems developed by different vendors and that range widely in age. It also provides easy-to-use reporting on Key Performance Indicators, enabling users to drill into the right level of detail for their role—whether operator or line supervisor, plant manager or executive.

This unparalleled, actionable insight enables manufacturers to achieve lower overhead and manufacturing costs, better manage capacity, extend the useful life of existing capital equipment, improve manufacturing consistency, energy use and first-pass quality—all critical to bottom-line results.

For more information, visit Manufacturing Intelligence.