Reaping the Wind in Real Time

High oil prices and global warming concerns have more people looking at renewable energy sources such as wind power. Wind power installations have unique challenges due to energy variability and load balancing as well as accessibility of the many generating stations. The OPC Server for Vestas Wind Turbines can provide continuous access to real-time information needed for equipment monitoring and making production decisions.

Harness the wind

People have harnessed the wind for energy for thousands of years, and technology has been steadily reinvented and improved. The cost of energy production is continually decreasing as strides are made in material usage, rotor design and turbine technology. This gives wind power more competitive footing with conventional fossil fuel-based energy sources. Successful integration of renewable energy into utility portfolios is increasing, yet owners and operators still face many business challenges.

Optimizing operations, effective maintenance and increasing the accuracy and timeliness of decisions all affect the bottom line--not to mention issues such as utility integration, accurate data analysis and forecasting, and scheduling energy output. All these business aspects require accurate, real-time data for making effective decisions.

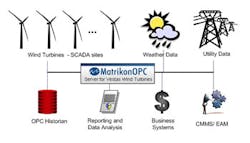

Wind power is converted to electricity by a wind turbine. A collection of wind turbines in the same location is called a wind farm. Production varies with the wind, turbine design and location. Individual turbines interconnect with a medium voltage collection system and communications network. These systems feed into a high voltage transmission line and connect to the electric grid. In addition to data from multiple generating turbines, information is needed about the substations and utilities, as well as key meteorological data. Wind farm systems may contain up to hundreds of windmills, covering long distances and harsh environments. Users need a reliable communication network capable of providing standardized information monitoring and centralized control and data storage.

Leading supplier of wind power

With more than 40,000 wind turbines installed, Vestas is the world's leading supplier of wind power solutions. The Matrikon OPC Server for Vestas Wind Turbines can provide real-time data access for remote supervision, control, and data acquisition required for operation and maintenance. The OPC Server also is a means of standardized communication among energy management centers and regulatory bodies. High-resolution data is essential for optimizing wind farm assets and realizing incremental gains critical to improving the bottom line. OPC helps overcome the challenges of not only gathering data from various sources into a centralized repository, but to also present the data that spans from different manufacturers, technological generations and geographical locations, in a consistent format.

OPC enables interoperability between disparate control systems, condition monitoring and production management systems. OPC DA provides plug-and-play connectivity between the various wind farm data sources. The OPC specification ensures that regardless of the underlying system and the product vendor, the interfaces will connect and exchange data in the same way.

Winds of change

OPC provides the means to manage wind farms in a standardized fashion by providing applications with real-time data and critical information on each point in the system. Standardizing access with OPC supplies a better way to manage wind performance and control assets. The Matrikon OPC Server for Vestas Wind Turbine Controllers gathers high-resolution, real-time data and gives end users far more capability to analyze and affect the operation of the wind farm, than the existing technology that much of the wind industry is now using.

For more information on OPC solutions from MatrikonOPC, visit www.matrikonopc.com.