Non-incendive barrier modules minimize risk of ignition

The modules limit energy to safe levels, which prevents arcing or sparking and allows live wiring on the device in a Class I, Division 2 or Zone 2 area.

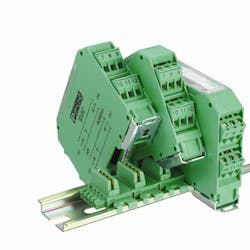

Two versions are available. The PI/NI-2D/24 protects 24 V digital signals in the event of a short circuit or over-voltage condition. The PI/NI-2I/I limits the maximum short circuit current to 24 mA in 4-20 mA loops. It can be installed with two-wire 4-20 mA transmitters.

Both analog and digital signal modules have two channels and can use the INTERFACE T-Bus connection system. The analog module can be powered from the T-bus, but the digital module does not require power.

Non-incendive barriers remove the need for bulky and costly explosion-proof or purged enclosures, sealed conduits, glands and fittings that are typically used in Class I, Division 2 areas.

Phoenix Contact is a world leader in electrical connection, electronic interface and industrial automation technologies. Phoenix Contact GmbH & Co. KG, Blomberg, Germany, operates 46 international subsidiaries, including Phoenix Contact USA in Middletown, Pa. Global sales exceed more than 1 billion euro annually. Phoenix Contact’s formal Integrated Management System is registered to ISO quality, environmental and safety standards (ISO 9001:2008,14001:2004 and 18001:2007).

For more information on Interface Analog or any other Phoenix Contact products, visit www.phoenixcontact.com.