Eliminate 40% Costs when Applying Drive Architectures

“I’ve gone out to plants and people don’t want to do it and I don’t understand why,” he says, pointing to cost savings in the 40 percent range when electing to go with this approach over traditional analog systems in the areas of engineering, control, system building, assembly and commissioning. “The benefits become clear once you do it.”

The benefits, says Richards, start with improved information. More information means more control over your processes. “In the past you were very limited in what information you could get out of the process. The drive is now an integral part of the hardware configuration for the PLC. Now, when you integrate a drive into the PLC bus you get a tremendous amount of information back from the drive.”

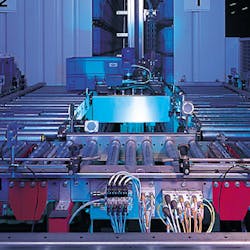

The benefits don’t stop there. In addition to improved control, reduced cost and increased productivity, Richards points to reduced infrastructure requirements – i.e.: less wiring – and a profound impact on the time required to set up or make changes to the production line.

Before joining Siemens, Richards used to work for the drive systems group at Quadrant Engineering Plastic Products, worldwide engineered plastics manufacturer based in Pennsylvania. His last assignment at Quadrant was the set up a system containing 30 drives.

“If you can imagine all the wiring required to connect 30 drives in analog then you can imagine eliminating all of that and just connecting them to a single purple cable. Your start-up time is significantly reduced. Start-up following install went from 4 or 5 days to one. We did it once in six hours.

“The whole Totally Integrated Automation approach really worked. The more we integrated into one project…it got quicker and quicker. It really did.”

What’s more, he adds, you have fewer points of failure meaning better reliability. “When I used to do it the old way I always had more analog failures. Since I started doing it this way I can’t recall one.”

UK-based Marston's brewery, home of the world famous Pedigree bitter, was an early adopter of networked drive technology and reaped significant benefits from its migration. D. Boothroyd detailed the Brewery’s experience for Computing & Control Engineering Journal.

For instance, wrote Boothroyd, Parameter settings on the variable frequency inverter drives that operate Marston’s bottling lines can be altered dynamically via the network without interrupting the operation of the line. Things like ramp up and ramp down rates, and maximum/minimum speeds, can be altered as the line is running.

Each drive has between 30 and 40 parameters that can be adjusted, from such basics as the voltage it runs at to more sophisticated aspects such as the percentage of torque the drive will generate. “By simply sending a data message on the network it is possible to modify any drive, either permanently or temporarily.

Additionally, networking provided the brewery with other benefits, including more delicate handling of bottles, improved plant integrity, and its inherent scalability provided a platform for flexible future expansion.

Today, it is easier than ever before to network drives into a single control system. All the control system vendors have systems that easily allow you to point and click and drag and drop your way through installation.

“In the Siemens world you have Simatics Manager and Drive ES,” says Richards. “You integrate everything into the software – all its network and configuration info. It’s really easy to set up, configure and control.

“Once you have them installed you go to the hardware configurator – the PLC processor, I/O configurator. Your drives show up as an option. Find the drive and drag and drop it onto your configuration. It’ll attach it to whichever bus technology you are working with – either Profibus or Profinet.

“Your next selection will be the amount of information you want to communicate back and forth to the drive. You can configure from 2 to 14 words each way. These words convey signals and commands such as ready, start, stop, alarm, etc. I usually use around six, but you may need to use more if you are working on a safety system, etc. Finally you program the address of the drive into the network. Once you do that and everything is wired up properly, the drive should be talking to the PLC.”