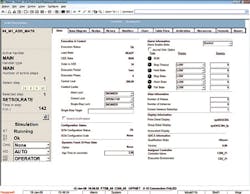

Small Controller Lowers Costs

It manages all continuous process control applications and optimizes

batch and sequence-oriented applications typically found at specialty

chemicals, pharmaceutical, food and beverage, and consumer goods

producers. Scalable from a single PC and controller to multiple

stations, the control system promotes plant reliability and flexibility

while lowering lifecycle costs for smaller manufacturing sites. It is

well-suited for smaller plants by allowing the manufacturer better

response to market changes while offering robust process and batch

control features. Because it requires less engineering effort to

configure and is easier to maintain than a PLC or large DCS, Experion

LS can help plants save up to $20,000 per year in support per system,

says the vendor.Honeywell Process Solutionswww.honeywell.com/ps973.455.2000