OPC Feeds Data from PLC to DCS

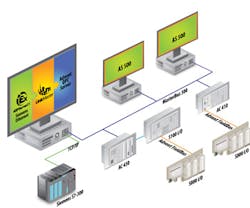

The Georgia Pacific paper mill in Yalova, Turkey, was faced with a few problems at the plant. In the water treatment portion, the paper plant was using a Siemens programmable logic controller (PLC) and needed to feed data into an ABB Advant OCS.At first, the paper mill wanted to connect in a classic way, using Profibus to link the Siemens PLC to the ABB Advant OCS. This type of connection can be very costly and time consuming to set up. The Profibus connection has complex programming requirements, and the distributed control system controller, when connecting to a slave, had to restart itself. Restarting the DCS controller, which may have to be done multiple times, stops the mill production each time.ASP Otomasyon, an OPC integrator and distributor based in Turkey, needed to develop an affordable and robust solution that kept up with the rate of the data feed. With many years of experience in the paper industry, ASP Otomasyon approached this problem by applying the use of Kepware Technologies' LinkMaster and KEPServerEX OPC Server with plug-in driver for Siemens controllers.The paper mills' request of transferring data from PLC to DCS is common and understandable, since the DCS has complex structures and operators prefer to observe and control every item from the DCS. With this in mind, ASP deployed the KEPServerEX application to read all the tags from the Siemens PLC. Then the company incorporated the use of LinkMaster to link this PLC data to the DCS.LinkMaster provides a means of bridging data from one server application to another and it requires no programming. Rather, LinkMaster uses a simple "Drag and Drop" method that will create links, and includes built-in scaling, user-access manager, error tracking, and write optimization capabilities, providing total control of data flow and application access. Link Groups are then created to form collections of OPC items that will be moved between OPC servers at a specified rate.With multiple Link Groups, LinkMaster controls how fast data is transferred from one OPC server to another. By using Link Groups with different update rates, the data transfers can be tailored to the needs of the application. While one item may need to be sent at high speed, other items in the application may need slower update rates. The adjustable Update Rate in Link Groups can be used to reduce network traffic and increase reliability of the overall application.During implementation of this project, ASP Otomasyon faced one problem:When the tag delivers new information, LinkMaster keeps the tag engaged (at the DCS) while writing the new value. The data would change every second and while the data was changing, the tag and the DCS were still engaged. This resulted in the operator being unable to select the tag while the data exchange was occurring.The problem was solved by creating and using new variables, which are then forwarded inside the DCS database. By doing this, the operator could reach the original tags while new tags were being read and written. The project was completed on time, within budget and is still working very well for the client.Visit Kepware to read the full LinkMaster OPC Server Solution.