PPT VISION's Sentinel Mold Protection Solution Minimizes Costly Repairs and Downtime

With each cycle of the injection molding process, mold presses run a high risk of experiencing severe damage from sticky slides and molded parts that are not ejected properly. The PPT VISION Sentinel offers the manufacturing industry a superior turn-key solution to protect their mold presses and tooling, avoiding expensive repairs and minimizing production downtime.

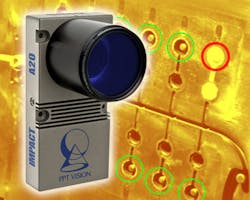

“While standard mold protection options use tool sensor solutions to simply detect the problem as it takes place, the Sentinel Mold Protection Solution stops the press and alerts operators before damage—such as mold crashes and broken tools—occurs,” said Mr. Bob Heller, President of PPT VISION. “Powered by the IMPACT™ Intelligent Camera product line, Sentinel offers an intuitive software interface that supports multiple cameras and inspection stages.” Heller adds, “This solution provides a strong value proposition, delivering more value for the dollar to customers worldwide.”

The Sentinel Mold Protection Solution supports up to four cameras. Each camera provides users the ability to configure up to five mold inspection stages, including the inspection of mold flash, short shot, part ejection, pin retraction, insert position verification and more. The software panels are pre-configured for mold protection applications; users simply point and click to select the desired inspection options before putting the system online. Plus, the touch-screen compatible, step-by-step intuitive software is designed to allow users to deploy the solution online within minutes—from the ground up.

The Sentinel also supports “head-less” mode operation. Through smart camera technology, the PC can be disconnected once inspection requirements are configured. The camera(s) are interfaced directly with the press control so the Sentinel continues to monitor the press, alerting the operators in the occurrence of problems.

A complete Sentinel Mold Protection Solution consists of one to four IMPACT cameras, application specific Infrared LED lighting and lens, Sentinel Software, and all required interconnecting components that interface with the mold press. Camera mountings are magnetic based for fast and secure, yet flexible deployment. Additionally, an optional industrial PC and monitor are available on a mobile cart for quick press-to-press transfer.

Sentinel is available in any IMPACT hardware platform. IMPACT camera options include 17 models, covering a full range processing power, color and monochrome CCD formats, and resolutions from 640 x 480 to 1600 x 1200 pixels. The Sentinel Software allows users full access to the camera settings, including shutter and gain controls as well as strobe settings for the lighting. The pre-configured operator panels and the intuitive software interface, coupled with the full range of IMPACT hardware options, makes the new PPT VISION Sentinel one of the most powerful and flexible mold protection solutions available in the market today.

To request additional information on the Sentinel Mold Protection Solution or to request a FREE demo copy of the Sentinel Software, call 952-996-9500 or e-mail [email protected].

PPT VISION develops and markets innovative machine vision technologies including smart cameras and high-end vision systems for a broad range of industry categories, including manufacturers of automotive components, electronic components, pharmaceuticals, semiconductors, medical devices, consumer goods, and plastics. For additional information contact:

PPT VISION,

6301 Old Shakopee Road, Suite A,

Bloomington, Minnesota 55438.

Phone: 952-996-9500.

FAX: 952-996-9501.

Email: [email protected].

Website: www.pptvision.com.