Painlessly Migrate from "Classic" OPC DA to OPC UA

With OPC Unified Architecture (UA), the OPC Foundation's next generation technology, the vision of "global" interoperability will become a reality. The new standard will break down the communication barriers that have been limited by OPC’s dependence on Microsoft’s underlying DCOM technology. Furthermore, the design of the new architecture works with any operating system without compromising the performance of the data exchange mechanism, making it the perfect solution for embedding OPC technology into devices.

New Applications Using OPC UA

Traditionally, OPC (with the exception of the OPC XML-DA specification) makes use of the Microsoft Distributed Component Object Model (DCOM), which is part of the Windows operating system. However, the downside of relying on DCOM is that it confines OPC technology to the Windows operating system. The manufacturing automation industry has been calling on the OPC Foundation to provide a new and flexible OPC standard that is independent from any proprietary technologies provided by an operating system vendor, while not sacrificing performance. The OPC Foundation and its members answered this call by developing a new Unified Architecture for OPC that is no longer dependent on underlying Microsoft (or other vendor’s) technologies.

The basis for OPC UA is its service-oriented architecture (SOA) no longer relying on operating system specific technologies. The OPC UA kernel is composed of a set of UA services that form an interoperability framework. This framework forms an autonomous entity with a defined interface to the underlying proprietary technology. Because of OPC UA’s independence from any operating system technology, it becomes easily portable to many hardware and software platforms.

OPC UA represents the future, and many (if not all) suppliers of OPC technology will begin their migration process to use this technology within the next few years. However, what can you do about this today? Currently, almost all OPC Client applications deployed in the field (e.g. SCADA systems) base themselves on the original OPC specification and thereby are not compatible with the new OPC UA standard. What is currently needed is a painless migration path that addresses this fact.

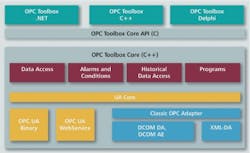

Softing, a leading provider of embedded OPC technology, has specifically redesigned its OPC development tools to manage today’s legacy requirements, while at the same time ensuring the easy migration from OPC DA, AE, and HDA to OPC UA. The latest development tools from Softing provide a built-in upgrade path to OPC UA, protecting the investment of OPC developers using the tools.

When using the toolkit’s software libraries that provide certified and UA-compliant functionality, upgrading current applications will not make any noteworthy changes to them. Already, some manufacturers of industrial automation products that use non-Windows operating systems (e.g. PLCs, field devices, or UNIX/Linux-based ERP systems) have begun development projects to embed this new technology into their offerings.

In addition, the OPC development tools minimize the time-to-market and maintenance efforts. Many companies have factored-in Softing’s extensive experience with embedding OPC technology into industrial components. For example, Schweitzer Engineering Laboratory (SEL) stated, “Softing’s OPC kits are essential when it comes to developing Web applications. With Softing’s development kits, a developer does not necessarily need to have expertise in SOAP or even the OPC protocol but can focus, instead, on the non-OPC-specific components of the application.”

Thomas J. Burke, President and Executive Director of the OPC Foundation, states the following: “Softing’s expertise and experience in providing industrial communication products and developer training in all facets of automation inclusive of OPC is being extended to fully embrace the OPC Unified Architecture. I’ve personally had the opportunity to attend a number of events/training sessions that Softing provides or has participated in, and I can say without hesitation that the quality and integrity of Softing’s offer is outstanding. I look forward to watching Softing be one of the premier providers enabling other vendors to successfully adopt and deploy OPC Unified Architecture products based on the products and services that Softing has to offer.”

Softing, a member of the European Steering Committee of the OPC Foundation and author of the OPC Book, actively contributes to the success of OPC by providing high quality OPC products, enabling their customers to stay in the forefront of the industrial communications technologies they deploy.

For more information on how can assist you, please visit www.softing.us.