OPC Enables Telemetry Software for Range of Data Sources

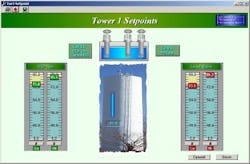

In telemetry, data sources are spread out over 100 plus miles from one end to the other. The ease of knowing what is going on everywhere is critical. Kelly Zini, President of Control Products Unlimited, points out, “A pump station and boosters may be moving water several miles in one direction. We have to know the level at the other end so we don’t overflow, and we have to watch the source to prevent pump cavitation. The challenge is to, in as real time as possible, let the source and destination ends know what each other are doing.” Continues Zini, “The Control Products Unlimited CPUtils SCADA systems software was designed from the ground up to solve tough telemetry challenges, regardless of the industry. Our goal was to have a solution that, once you set your tags up for each of the locations, you identify a destination and the source, and the software maps the data between the two.” One of the challenges that Control Products Unlimited (www.cputil.com) faced was providing reliable connectivity that handles the unique requirements of telemetry systems while being able to support the widest range of hardware possible. Zine adds, “Our goal was to design a simplistic development environment that incorporated powerful features such as distributed processing, generic data storage, graphical process representation, and a wealth of reporting options. The most important requirement was that we must support connectivity to all major industrial equipment and field instrumentation brands, and we did not want to be in the driver writing business, which is where OPC comes in.”According to Zini, “Because OPC is well accepted, we knew it had the potential to allow us to leverage the R&D efforts of best-of-breed software providers focusing on connectivity, while we focused on our unique telemetry application value add.” Control Products Unlimited chose to work with Software Toolbox Inc., located in Matthews, N.C., and use the TOP Server OPC Server lineup (www.toolboxopc.com), powered by Kepware, as its platform for connectivity. Adds Zini, “Software Toolbox has a great reputation for responsive support and high technical aptitude, combined with a product offering that gave us access to just about any device type we could imagine. Throughout our multi-year development cycle, they supported us all the way to help us deliver a solid platform.” The results for CPUtitlities users have been impressive as evidenced by what they have had to say: "Converting our remote site communications from dial-up to wireless Ethernet was easily accomplished within a matter of minutes. The CPUtilites and TOP Server software provide a high performance and stable environment for housing our mission critical data." Ron Malcom, Rogers County Rural Water District Operations"The move from a proprietary control system to an OPC based solution has dramatically improved the operation of our facility. The wealth of tools comprising the CPUtilities and TOP Server products have allowed us to perform more maintenance tasks in house decreasing downtime and outsourced support costs." Jerry Gammill, Washington County Rural Water District ManagerTo learn more about the CPUtils story and product and how they leveraged OPC please click here.To learn more about solutions that Software Toolbox can provide using OPC DataHub and TOP Server, please visit www.softwaretoolbox.com/opc.