Robust Integration Between Process and Business Layers

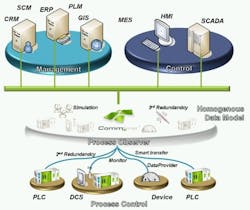

Nowadays, to have the edge over competitors, modern manufacturing automation systems have to be employed. They consist of Information Technology (IT) and control systems at business and process levels. To make the automation process more and more beneficial, the systems have to be integrated. From integration, we should expect additional effectiveness as a result of synergy and real-time macro optimization effects.

System integration means the necessity of establishing an association between components and actually building an information architecture, which has a great, direct impact on the final robustness, maintainability, expandability, dependability, functionality and costs.

Generally, one of the following methodologies can be applied:

- Peer to peer model: A common practice is to achieve short-term ad-hoc objectives by creating dedicated point-to-point connectors wherever it is useful. In this approach, the number of logical links rapidly grows with the number of components and, finally, we have to deal with communication chaos.

- Totalitarian Model: The next option is to use an “all in one” product that is dedicated to all functions and usually provided as one complex total system – a super-system. If strictly observed it could be a blind path, because the result is vendor-related forever.

- Process Observer Model: This is a kind of a virtual layer, which is a “big picture” of the underlying process layer composed of unit data randomly accessible to the process and business management systems by means of a unified and standardized interface. It is like a bridge connection between the plant-floor, process and business management levels.

- Functionality

- Communication: To meet scalability and open connectivity requirements, it exposes an OPC interface to be consumed by upper layer applications. Because not all applications support the OPC standard, an additional software package, DataPorter, offers SQL and XML connectivity.

- Simulation Provision: CommServer offers the possibility of creating simulators and publishing simulation data as OPC tags. Using simulators instead of communication drivers, it is possible to switch between production and test environments.

- Resource Monitoring: CommServer allows the publishing of diagnostic data gathered from communication and processing devices as OPC tags.

- Simulation Provision: CommServer offers the possibility of creating simulators and publishing simulation data as OPC tags. Using simulators instead of communication drivers, it is possible to switch between production and test environments.

- Resource Monitoring: CommServer allows the publishing of diagnostic data gathered from communication and processing devices as OPC tags.

- Three levels of redundancy

Using the middleware archetype with only one common component creates a single point of failure. The proposed solution offers three levels of redundancy to eliminate the risk.

- Hardware: We have two options—boxes and components redundancy.

- Communication paths: CommServer is designed to recover from the failure of a device communication path by switching to another available one. The crucial feature of paths redundancy is the provision of the routs multiplication without the necessity of transferring the same data over the network many times and controlling the availability of all the paths.

- Signals: CommServer allows the definition of replicated signals. Thus, if one signal fails, the other one is available as a single OPC tag.

- Hardware: We have two options—boxes and components redundancy.

- Communication paths: CommServer is designed to recover from the failure of a device communication path by switching to another available one. The crucial feature of paths redundancy is the provision of the routs multiplication without the necessity of transferring the same data over the network many times and controlling the availability of all the paths.

- Signals: CommServer allows the definition of replicated signals. Thus, if one signal fails, the other one is available as a single OPC tag.

- Optimal communication

Because of its role, the CommServer has to implement the following unique features optimizing utilization of the underlying communication infrastructure.

- Multi-protocol capability

- Multi-medium capability

- Multi-channel connectivity

- Adaptive Retry Algorithm

- Adaptive Sampling Algorithm

- Optimal Transfer Algorithm

A case study proves a competitive advantage of using CommServer as the collaboration platform of three power plants for synergy effect saving $5 million per year.Read the whole article…For more information, visit www.commsvr.com.- Multi-protocol capability

- Multi-medium capability

- Multi-channel connectivity

- Adaptive Retry Algorithm

- Adaptive Sampling Algorithm

- Optimal Transfer Algorithm