Mine Uses OPC to Integrate Expert System Control

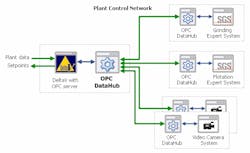

Minera San Cristobal, owned by Apex Silver and Sumitomo Corporation, is one of the largest silver-zinc-lead mining projects in the world. The mine, located in the Potosi district of southwestern Bolivia, was opened in 2007, and is expected to produce approximately 450 million ounces of silver, 8 billion pounds of zinc, and 3 billion pounds of lead.As described in a companion article (see link below), the engineers at the San Cristobal mill used the OPC DataHub from Cogent Real-Time Systems, located in Georgetown, Ontario, Canada, to connect their DeltaV supervisory control and data acquisition (SCADA) system to a SQL Server database in the corporate offices. After witnessing the success of that project, the engineers decided to connect their two SGS expert systems to DeltaV in a similar way. “We saw how well the OPC DataHub transported OPC data across the network,” said Mario Mendizabal, Production Engineer at Minera San Cristobal, “so we thought it could help us connect to our Grinding and Flotation Expert Systems.”In the San Cristobal mill, the ore extracted from the mine is crushed, ground and refined through flotation process to yield concentrates of silver, zinc, and lead, which are then shipped abroad for final smelting. These processes are monitored and controlled using the DeltaV system. Although the DeltaV system allows an operator to input setpoints and other values directly into the system, Mendizabal and his team wanted to apply an SGS expert system to optimize two critical parts of the mineral refining process: grinding and flotation. Each expert system runs on a separate server. To add to the challenge, the Flotation Expert System also requires real-time data input from two banks of 25 video cameras. These cameras monitor the size, speed and other qualities of the bubbles as they lift the valuable mineral particles to the surface, where they can be skimmed off as foam. There is one bank of cameras for the zinc flotation circuit, and another for lead. Each of these five systems—DeltaV, the Grinding Expert System, the Flotation Expert System, and the two camera systems—needed to be connected in real time.Fortunately, each system had an OPC server. What was needed was a way to bridge the OPC servers, aggregate their data streams, and tunnel the data across the network for the other systems. Based on previous success using the OPC DataHub, Mendizabal chose to apply it to this task. He already had an OPC DataHub connected to the DeltaV system. So he just installed an OPC DataHub on each of the SGS servers, and each of the camera system servers. Then he connected those four OPC DataHubs to the main DataHub running on the DeltaV server.“It didn’t take long at all to get the system configured,” said Mendizabal. “Since it is tunneling across the network, we avoided DCOM [distributed component object model] settings and networking issues entirely. The connection is completely secure, and rock-solid.”When the expert systems are switched on, plant data flows from DeltaV to the Grinding and Flotation Expert Systems. These systems continuously and intelligently adjust the values of the setpoints, and send them back in real-time to the DeltaV, which passes them along to the relevant process. To make its calculations, the Flotation Expert System also takes into account the real-time data that is streaming in from the two Video Camera Systems.“It is very important to know that when the expert system is controlling the plant we are trusting our production to the OPC DataHub,” said Mendizabal. “We are very pleased with its performance, and highly recommend it for this kind of mission-critical work.”For more information on this application, see the companion article.For more information on OPC solutions from Cogent Real-Time Systems, visit www.opcdatahub.com. Or click here to go directly to the companion article on OPC DataHub.