New Drives Family Transparently Employs OPC Communication

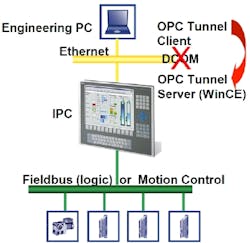

Lenze is one of the leading industrial innovators of products used for “driving, positioning, and transporting.” The company has about 3,200 employees worldwide, some 300 of whom work in Research and Development, focusing on products, solutions, systems, and services for mechanical and electronic drives. With its new L-force product line, Lenze introduced a new concept of PC-based automation for high dynamic performance, precision and force. Among others, this approach includes the following advantages:Remote maintenance via TCP/IPSimple vertical integration using OPC technology.L-force represents an innovative and scalable product range covering all areas of drive and automation technology, embedded in a well thought through service concept. During the conceptual phase of designing the L-force system, Lenze’s design team decided to use OPC technology as the data exchange mechanism. All drive products within the L-force product family offer an OPC software interface.The OPC interface provides a communications link between the L-force Industrial PCs and the L-force Engineer software on an engineering PC.L-force Engineer is configuration software for planning, commissioning, monitoring, and diagnostics. The L-force Industrial PC is a controller, visualization system and, at the same time, a gateway between L-force Engineer and field devices running on a fieldbus (e.g. CAN-bus). The OPC interface also provides data to HMI stations.The L-force industrial PCs are running Windows CE, representing an excellent, compact solution that meets the real-time requirements of motion applications. However, one drawback of Windows CE is its limited support of Microsoft’s DCOM technology. In fact, starting with Window CE 6.0, Microsoft will stop including its DCOM technology into this operating system. For this reason, Lenze’s design team decided against deploying DCOM technology, posing a problem because OPC communications is based on DCOM. Lenze found a solution to this problem by embedding the OPC Tunnel middleware product from Softing, based near Munich, Germany, into the L-force hardware.Lenze’s design team standardized on the OPC Tunnel based on the software’s performance and immediate availability for use in a real-time environment under Windows CE .NET. Lenze also factored in Softing’s extensive experience with embedding OPC technology into industrial components. The OPC Tunnel, part of Softing’s Easy Connect Suite, combines high performance with a robust communication link between OPC components. Communications between the client-side and server-side OPC Tunnel components is realized over a TCP/IP connection (encrypted, if desired). The data between client and server applications is tunneled via TCP/IP, bypassing DCOM completely, eliminating time-consuming DCOM setup work. “We are very pleased with the performance of Softing’s OPC Tunnel within our new L-force product family,” said Mr. Thomas Maschler, head of Product Management Automation. “In the past, DCOM configuration issues were the leading cause for support calls. With L-force, we do not see any support calls related to OPC. This fact demonstrates that by employing Softing’s OPC Tunnel, we achieved our goal to seamlessly and, more importantly, transparently integrate OPC technology into our product line.” OPC has become a widely accepted means of exchanging data between devices. This is one of the main reasons Lenze chose to integrate OPC technology into its product line. Today, end-users already have access to many OPC client applications for visualization and other purposes that support OPC XML-DA and OPC DA. Designers can easily enhance products that use OPC, like the L-force Industrial PCs, by adding Softing’s portable OPC components. This allows system developers to concentrate on transmitting data and not on learning the intricacies of DCOM, or other technologies.Softing, a member of the European Steering Committee of the OPC Foundation and author of the OPC Book, actively contributes to the success of OPC by providing high quality OPC products that enable our customers to stay in the lead. For more information on how Softing can assist you, please visit www.softing.us.