Dynamic Duo of Industrial Connectivity

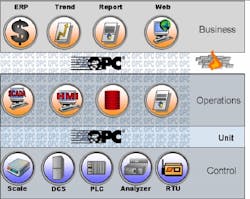

Ever had a system integration project that required superhuman effort to complete? It’s almost criminal to think of the problems users face when attempting to create an integrated system of multiple-vendor products and applications. Unfortunately, no single protocol is going to swoop in and save the day. It requires integrating multiple complementary protocols, each with individual strengths, to achieve the goal of a true enterprise system. Leading the way is the dynamic duo of OPC and Modbus.Although the physical setup of manufacturing or process automation systems varies greatly, the majority can be represented by a three-tier architecture consisting of the Control, Operations and Business layers. The Control layer represents low-level data transfer and control. The Operations layer includes software products such as visualization and supervisory applications, data storage, calculation and other automation packages. The Business layer represents the higher-level visualization and reporting packages, decision support software, advanced analysis and web-based applications. (See diagram.)Just as each superhero has strengths and weaknesses, there are also distinct connectivity requirements between tasks performed by applications in the multiple levels of the enterprise hierarchy. The protocols used at each layer, and used to create interoperability between the layers, need to be targeted for different applications.Truth, Reliability and the Interoperable wayAt the Control layer, the heartbeat of any industrial process is the communications network between the transmitters, controllers and other control and measurement devices. The key requirements in keeping the data flowing are robustness, determinism and compatibility. For many years, proprietary networks and individual vendors held tight-fisted control over this layer. Users feared the consequences of expanding or making changes to their systems, and desperately needed someone to free them from the proprietary constraints.Modbus is an alternative to proprietary networks. While it is often classified as a fieldbus protocol, Modbus, with its various enhancements, is suited to an even wider range of communication applications. One of the reasons for its success is that Modbus is a simple and sturdy protocol. It may not be as flashy or sophisticated as some other interfaces, but it gets the job done. As a straightforward protocol, it is easier and faster to code, apply and troubleshoot than more complex interfaces. For this reason the serial versions of the Modbus protocol have long enjoyed a position of market leadership. Its reliable, consistent nature has also led to a rapid acceptance of Modbus TCP as an Ethernet-based communication protocol. If the Control layer is considered the working elements, then the Operations layer provides the direction. The Operations layer contains the applications that transform data into useful information and knowledge, and bridges the lower and higher hierarchies.Organizations need large amounts of data, derived from multiple sources and quickly delivered to many destinations simultaneously. Proprietary systems and single-vendor dominance is also a dark reality at this layer. To achieve the benefits of flexible, scalable and interoperable systems, without extortionate integration costs, the protocol for this level should be standardized across multiple vendors, systems and products.These characteristics make OPC well suited for the task of connecting the Operations layer with the other levels. OPC offers separate specifications to address different data semantics, including real-time data, historical data, alarm and event information and batch data. The interfaces are comprehensive enough to provide the functionality users require, yet simple and practical to implement, which results in wide vendor acceptance. This includes the availability of OPC products for complementary protocols, most significantly Modbus.Taking Care of BusinessThe trend at the Business layer, as well as in parts of the Operations layer, is towards open interfaces and web- or service-based technologies. Applications at the higher level are concerned with consolidating information from various sources, compiling data into reports, and summarizing those into key performance indicators and other decision-support metrics. It is therefore important that there be easy access to all the underlying sources to allow for aggregating and analyzing data across multiple functions and applications.Early speculation is that OPC Unified Architecture (UA) will be the protocol of choice for integrating the Business layer with Control-level protocols such as Modbus. OPC UA provides a rich information model and standardized messaging, which will provide interoperability between the various event-processing and automated analysis applications. Also, any cross-enterprise management system must be scalable and secure. All aspects of the OPC UA specifications have been designed with both robust security and a wide range of scalability in mind.As industry standards evolve and strengthen, those with wide adoption and proven interoperability will continue down the road of enterprise integration while others will fade into obscurity. System architectures will always involve a selection of protocols and standards. The key is choosing well-established, complementary protocols like OPC and Modbus that offer the best interoperability options. For more information visit www.matrikonopc.com.