OPC Enables System Integrator Success

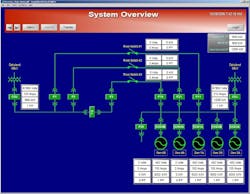

In “OPC years,” Russ Ropken has been around the technology for a long time—more than half the life of the OPC specification. Starting back in 2000, Ropken worked with Software Toolbox, based in Matthews, N.C., to provide OPC connectivity to Siemens S5 programmable logic controllers (PLCs). Since then, Ropken has started and built a successful systems integration business, the RSICompany.com, and credits the openness of OPC as one of the factors that has enabled his business’s success. Ropken notes, “OPC has enabled me to solve connectivity challenges from simple to complex, without having to resort to writing custom code. This has allowed our company to focus on solving the customers’ business problems.”RSI provides solutions in a variety of industries, but does a great deal of work in the water and wastewater, oil and gas, and power transmission and distribution industries. RSI has had great success with OPC in an application that involves monitoring citywide meters for a municipality system. The city had the foresight to lay fiber optic cable throughout the city, providing a strong communications infrastructure.The municipality has various types of Modbus devices in the field. RSI chose the Software Toolbox TOP Server Modbus Suite OPC server to provide the connection to the human-machine interface (HMI) and supervisory control and data acquisition (SCADA) system from Iconics that was being installed. According to Ropken, “The Ethernet Encapsulation feature built into TOP Server made this project a slam dunk, because it was easy to setup and did not require any third-party virtual communication port software. The flexibility of the Modbus interface in TOP Server made it easy to insure we got the data we needed, when it was needed.”Another RSI success involved working with a major supplier of industrial switchgear to provide Modbus connectivity. In this project, the ability of an OPC Server to provide a layer of insulation between different field devices and the HMI/SCADA system proved to be key to success. RSI had configured the system to talk with one brand of Modbus devices and, later, had to switch to some GE Power Meters. Because tags had been configured in the OPC Server, and the HMI/SCADA system only knew a tag name, making the change was a snap for RSI. The company simply exported the tag database to a CSV file, made a few address changes in an Excel spreadsheet, re-imported it, and the system was up and running with totally different hardware downstream, but without having to make any changes on the HMI side. It’s not just about the technology, as Ropken adds, “The OPC technology has in itself been great for my business, but I’ve also learned that it takes more than just the technology to make things successful when using OPC. I’ve been working with Software Toolbox for so many years, I found out how much they had spoiled me with good care, and then I learned why. I had the opportunity to work with another supplier’s OPC product that had not been OPC Compliance tested, and it wasn’t as good an experience as I was used to with Software Toolbox.Ropken continues, “It was then that I learned more about OPC Compliance testing for servers, and Interoperability testing for both. I learned that Software Toolbox has been Compliance and Interoperability Testing its products for seven years, which, combined with their excellent tech support team, made me realize it takes all three to have success with OPC. I would recommend purchasing OPC solutions only from vendors who had invested in compliance and interoperability testing, so you can have as great an overall experience as I’ve had with OPC.”For more information on OPC solutions from Software Toolbox, visit www.softwaretoolbox.com/opc.