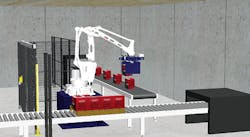

RobotStudio Palletizing PowerPac

The company integrated its PickMaster 5 palletizer programming technology into its RobotStudio simulation environment. The result is the ability to create a fully simulated robotic palletizing program that can also be downloaded directly to a robotic system on the factory floor. This simplifies the task of programming complex robotic palletizing applications, and provides programming software that allows users to configure, simulate and program robots and grippers for palletizing solutions in one step. The software automatically generates a RAPID application program that commands the activities of the robot. Users can determine if the robot can reach all pick and place locations within the work cell while still in the conceptual phases of a project. Once system layout is established, the correct robot can be selected for the application.

ABB Robotics – North America

www.abb.com/robotics

248.391.9000